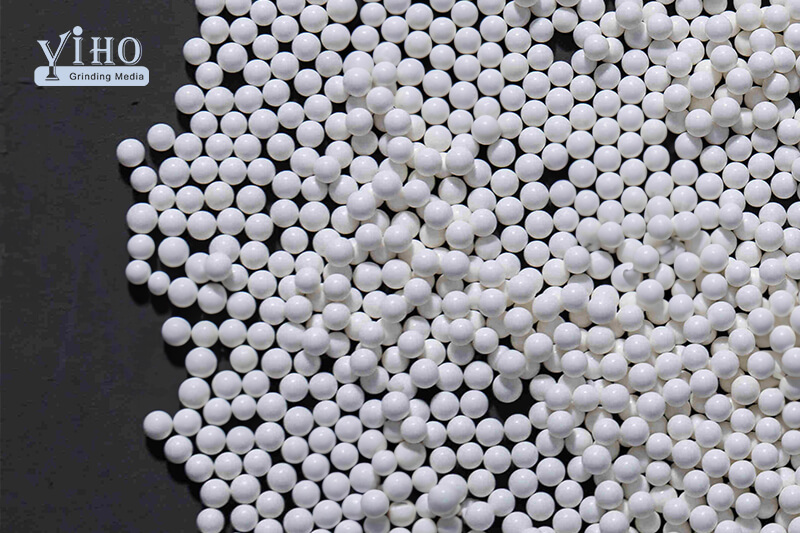

Ball mill alumina grinding media

This alumina grinding media possesses excellent thermal properties. So you can grind down to the particle size you need to achieve.

Better for some applications than porcelain, flint pebbles, or natural stones, Yiho Alumina grinding balls are precisely engineered, down to the nanometer.

Because when it comes to your ball milling process, every nanometer counts.

Advantages of Alumina (Al2O3) Grinding Balls

High performance wear resistant alumina ceramic balls are used in grinding and milling various materials.

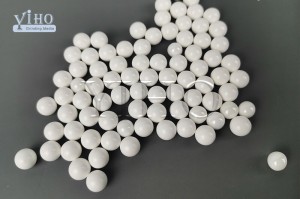

Different sizes of alumina grinding balls are available: <1mm, 1.5mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 13mm, 15mm, 20mm, 30mm, 40mm, 50mm. 60mm

The alumina grinding / milling media balls are extensively used in the fields of Paints, Inks, Geology, Metallurgy, Electronics, Ceramics, Glass, Refractory, Chemical Engineering, etc

Additional Information on Alumina Milling Media Balls

Pre-grinding the coarse, hard materials with large balls

The use of many small balls will increase the fine portion of the materials when the grinding time is increased

A higher percentage of the grinding balls will accelerate the grinding process

Main specifications of Alumina (Al2O3) Grinding Balls

|

DESCRIPTION |

PROPERTIES |

|

Shape |

Spherical, cylindrical |

|

Color |

White |

|

Alumina |

60%, 75%, 92% |

|

Ball size |

0.5-30 Rolling Type 25-60mm Pressed Type |

|

Hardness |

7-9Mohs |

|

Self Wear Rate |

≤0.08g/kg.h |

Other

Other Alumina Grinding Balls

We also have available all sizes of Al2O3 balls in between Φ0.5-1mm and including Φ60mm. Other contents of Al2O3 60%, 75%, 92% , 95%, and 99%.

Choice of Grinding Jars & Grinding Balls

In order to prevent excessive wear abrasion, the hardness of the grinding jars and the grinding balls must be higher than that of the material used for grinding. Normally, grinding jars and grinding balls of the same material should be chosen.

These are general recommendations: the size of grinding jars and grinding balls should be determined experimentally if necessary.