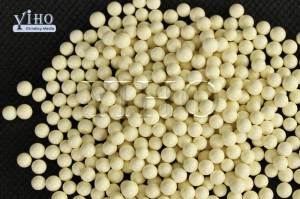

Polyurethane grinding ball

Product Description

Polyurethane ball is zero pollution medium ball which purchased by part of the specific high-tech enterprise. Our company adopts the special processing technology to ensure the concentricity of the inner metal ball and outer polyurethane lining, greatly improved its service life, and safety character. Now it is widely used in the grinding and mixing of all kinds high grade materials.

Polyurethane grinding balls are mainly used for material mixing and are wrapped with polyurethane outside the iron core.

Polyurethane grinding balls are widely used in vibration damping plates, punching, stamping, sheet metal calibration, and areas with high insulation and lifespan requirements for heavy-duty machinery.

Polyurethane grinding balls are used in our company's planetary ball mills, drum ball mills, stirring ball mills, and other ball mills to ultra-fine grind and disperse materials.

Our company can manufacture various kinds of ceramic grinding media professional, is a high and new technology enterprise, has passed ISO9001 quality system certificate, can make high wear resistance and high strength aluminum zirconium silicate composite beads, and other production process, we has a patent for invention, production,received extensive recognition and application at home and abroad.

Our product, include all kinds of grinding media(zirconia bead, alumina bead, zirconia silicate bead, ZTA bead) is mainly used in coating, paint, printing ink, ceramics, ink, electronic ceramics, titanium dioxide, pesticides, Kaolin, calcium carbonate, special chemical and other industries, zirconia bead, mainly used in Nano materials(such as lithium battery, barium sulfate, grinding ceramic ink, etc.)

Technical Data

|

Specific Density 1 |

1.3kg/L |

Tear Strength |

40-100KN/m |

|

Shore A Hardness |

35-95 |

Tensile Strength |

30-50MPa |

|

Akron abrasion |

<0.053(CM3/1.61km) |

Deformation |

<8% |

|

Working Temperature |

-25-80℃ |

Insulation Strength |

Excellent |

|

Expansion strength |

70KN/m |

Grease resistant |

Excellent |

Advantages

1. High wear resistance and strength

2. Chemical resistance

3. Good tensile strength

4 High elasticity

5. High pressure load resistance

6. Strong shock absorption

7 Tear resistance

8 Radiation resistance

9. High strength, high load-bearing and shock absorption cushioning

10. Good adhesion to metal and a wide hardness range, ranging from Shore A10-100.

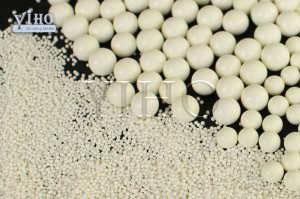

Specification for polyurethane coated iron core grinding balls

Diameter Φ 15mm- Φ 30mm (special requirements can be customized)