Rubber backed&Composite ceramic liners

-

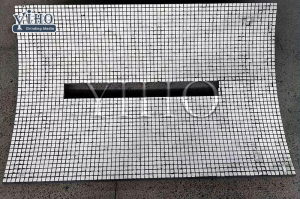

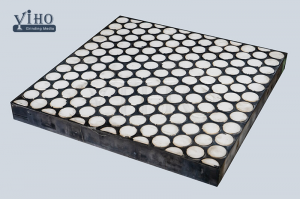

Steel backed Weldable Ceramic Tiles composite wear mats

The steel backed ceramic Mats have superior wear resistance. Liners comprising of high alumina ceramics and energy-absorbing rubber cushions which are more impact resistant. These features will also extend the wear life of your production line, and reduce maintenance and downtime.

-

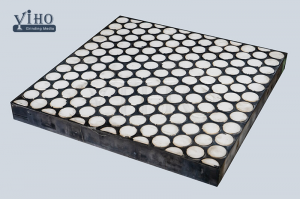

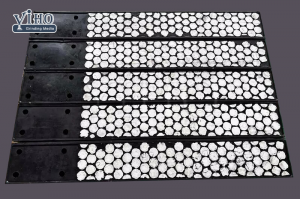

Wear Resistant Rubber Ceramic Panels

Wear Resistant Rubber Ceramic Panels is new generation composite panels, a combination of wear resistant alumina ceramic Hexagonal ceramic tiles vulcanized in resilient rubber base.

-

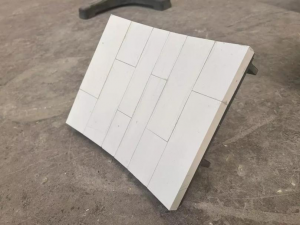

Rubber Embedded Ceramic Wear Tile Panels

Ceramic wear liners range include composite ceramic liners or Steel backed and studded as per requirements. We also have a range of molded ceramic in rubber with CN backing. The liners can be customized depending on the application.

-

Hybrid Liner Rubber Ceramic Matrix

Joined using a special process, the Hybrid Liner combines two liner materials and their favorable properties. The interior is made of polyurethane and protects the residual limb and bony structures thanks to its shock absorbing characteristics. At the same time, it ensures optimum pressure distribution across the entire residual limb, both for passive and active generation of the vacuum. The outside of the liner and the integrated vacuum flap are made of silicone, proven in everyday use thanks to its robustness. This is particularly important when the vacuum flap is folded over the inner socket to create an airtight seal for the system.

-

Hot Vulcanization Rubber Ceramic Composite Wear Panels

YIHO Wear Panel solutions are ideal for a wide variety of mining, mineral processing and material handling for protection against extreme wear.

-

Impact & Abrasion Resistance Rubber Backed Ceramic Liner

Alumina ceramic lining plate is a high abrasion-resistant wear product, it is a combination of high alumina ceramic tiles and natural rubber.

High alumina ceramic lining offers wear protection and can extend service life of chute or other equipment significantly, wear life of high alumina ceramic is approx. 5 timers longer than rubber and 10 times longer than steel.

-

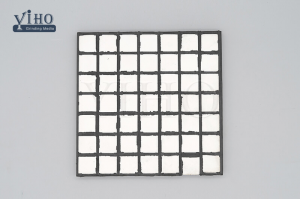

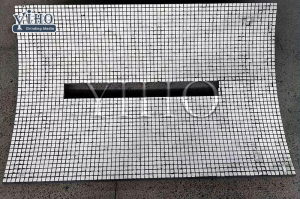

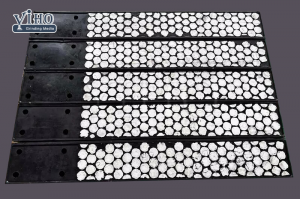

Hexagonal Tile Type Wear Resistant Rubber Ceramic Mat

Wear Resistant Rubber Ceramic Panels is new generation composite panels, a combination of wear resistant alumina ceramic cylinders/ceramic tiles vulcanized in resilient rubber base. The alumina ceramic surface provides exceptional resistance to wear, while the elastic property of the rubber effectively dampens the impact forces which can crack the ceramics. Rubber also helps to substantially reduce the vibrations, sounds, and the impact shock generated from impacting rocks. Laid out in zigzag and brick pattern, ceramic tiles/cylinders is an excellent feature for handling large material volumes at different angles without developing a wear pattern. As excellent impact and wear resistant material,The panel is suitable for feeders, chutes, bins, transfer points, in conveyor systems, screen feed plates, mill discharge chutes, bunker etc. The major applicable industries are Coal fired power plants, cement plants, blast furnace plants and host of other industries which requires high impact abrasion resistant surfaces.

-

HEAVY WEAR PROTECTION Ceramic Rubber Liner Materials

Yiho offers a number of custom wear-resistant rubber-ceramic liner solutions that provide long-term protection for Mining equipment.

-

HEAVY DUTY SKIRT LINERS (CERAMIC CANOE/Skirt LINERS)

YIHO has been manufacturing wear liners of all types for over 25years. From Bolt on to weld in, canoe liners or skirting liners, with steel back or ceramic face we can supply all your requirements.

-

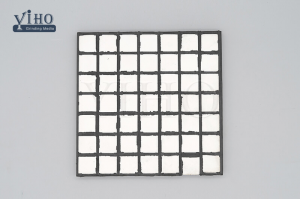

Engineering Wear Ceramic Matrix

Abrasion is always unavoidable in the processing and transport of bulk materials. The falling material flow causes particularly strong impact. We offer our customers best solutions with the high-quality ceramic wear matrix(with/without steel plate and bolt), in order to achieve an optimal result in increasing the impact resistance and reducing the abrasion and noise.

-

Conveyor Chute Lining Impact Liner Panel

Chute Linings are designed to be an integral part of a conveyor system. Our pre-engineered chute lining protects and cushions the chute from the material being handled; Skirt Liners prevents fugitive materials from escaping and damaging the conveyor loading areas. We can build, design, fabricate and install chutes, and also repair and re-align existing chutes.

-

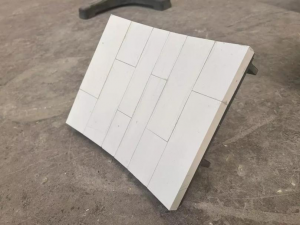

Chute ceramic Tile wear liner

The ceramic wear liner backed steel plates are hot vulcanized together with the high tensile strength nature rubber sheet and 3~10mm steel backing plate. As a result the ceramics wear liner will have both advantages of the rubber impact resistance and ceramic wear resistance.