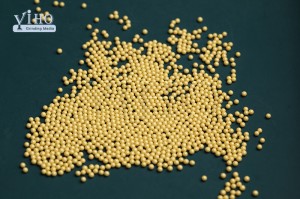

Ceria Zirconia Gridning Ball

Product Description

Ceria Stabilized Zirconia Bead is also one of typical ceramic grinding media. As the material contains "Cerium", the density of ceria stabilized zirconium oxide is about 6.2 g/cm3, which is the highest among the different types of ceramic grinding materials. Because of this feature, Ceria-Zirconia beads can be used to mill even high viscosity materials, in which other media may float.

The high density of cerium stabilized zirconium oxide beads allows smaller sized grinding bodies, which means that there can be more body per charge, and offering more touch area and narrower space between the bodies. As a result, grinding efficiency is higher and grinding time can be shorter.

Ceria Stabilized Zirconia is very similar to Yttria Stabilized Zirconia, both of them have hardness, preferable fracture toughness, high purity and are superior resistant to wear and corrosion. cerium zirconium oxide beads have also very good grinding efficiency and favorable properties compared to grinding balls/beads in lower density. For both horizontal and vertical mills, ceria stabilized grinding bead can be used effectively. It can be used ideally in many manufacturing fields due to its outstanding physical characteristics and lower price relative to yttria stabilized zirconia Bead. For instance, for grinding CaCO3 for paper industry and other products in the paint and ink industry.

Features

-Long lifespan: 30 times longer life than glass beads, 6 times than zirconium silicate beads.

High efficiency: around 6 times higher than glass beads; 2 times than zirconium silicate beads.

-Excellent wear resistance and fracture toughness is especially suited for high-solid-phase high viscosity, high hardness of the paste for grinding and dispersing of pure; good match at the same

time high input energy and the high shear machine sanding.

Applications

It is suitable for large capacity vertical mills for dispersion of CaCO3.

It is suitable for high-efficiency horizontal mills.

It is suitable for the production of high-viscosity paints and inks.

It has high wear-resistance and a bright brown color, so there is no contamination caused by thecolor of beads. It is being used for TiO2 makers that require a true white color.

It has high grinding efficiency, making it suitable for aqueous agricultural chemicals.

Chemical Composition and Physical Properties

|

Chemical Composition and Physical Properties |

||

|

Composition |

Zr02 |

0.8 |

|

CeO3 |

0.2 |

|

|

Bulk Density |

5.98~6.05g/cm3 |

|

|

Packing Density |

≥ 3.90 |

|

|

HV Hardness(GPa) |

≥ 11 |

|

|

Standard Size |

0.4-10mm |

|

|

Sphericity |

≥ 95 |

|

|

Packing |

25Kgs |

|

Package

Different package as to meet different customer’s requirements.

Wooden Crates Drum Plastic Pallet Bulk Packing Plastic Bucket