High alumina Ceramic Wear resistant Tiles

High alumina Ceramic Wear resistant Tiles Introduction

Alumina ceramic tiles for coal and other material handling and processing industries. Ceramic linings provide long-lasting solutions to the problems caused by abrasive wear and corrosion in a variety of hostile environments. Alumina ceramic linings will outlast lower grade materials commonly used to line or protect processing and material handling equipment, including Basalt, stainless steel, carbon steel and wear resistant plates, by factors of 3 to 15 times.

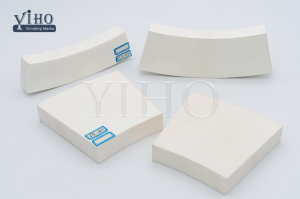

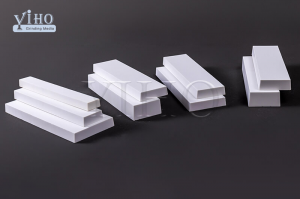

YIHO wear resistant ceramic tiles can be cut into any shape and are easy to install and maintain. They are suitable for both wet and dry processing applications. Advanced ceramics combine high strength and toughness with extreme hardness to deliver exceptional wear resistance.

The ceramic pipe tiles,also called taper tile or Trapezoidal tile, are used on a range of equipment including pipes, tanks, chutes, pumps, flotation cells, thickeners, launders and feed spouts or chutes.

High alumina Ceramic Wear resistant Tiles Technical Data

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

HC-ZTA |

ZrO2 |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

≥75% |

/ |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥21% |

≥95% |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

>4.10 |

>5.90 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1350 |

≥1100 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥90 |

≥88 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥400 |

≥800 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

≥2000 |

/ |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥4.5 |

≥7.0 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

≤0.05 |

≤0.02 |

High alumina Ceramic Wear resistant Tiles Advantages

• Zero friction against minerals.

• The highest protection against abrasion and corrosion.

• Wear protection up to 400°C.

• Longer life than traditional wear protection.

• Reduce downtime and maximize your plant's productivity.

High alumina Ceramic Wear resistant Tiles Application

Yiho high-density Ceramic Alumina Tiles are a proven performer, and are ideal for use across a variety of industries, including:

• Hard Rock

• Gold

• Copper

• Coal

• Minerals

• Gravel

• Sand

• Lime

High alumina Ceramic Wear resistant Tiles Advantage

Typically ceramics will last approximately five times longer in a chute lining applications and three times the life of rubber in a pipe spool. Many factors need to be considered when selecting the correct ceramic liners, such as angle of impact, particle size, particle density, velocity and general construction that the ceramics will be applied to