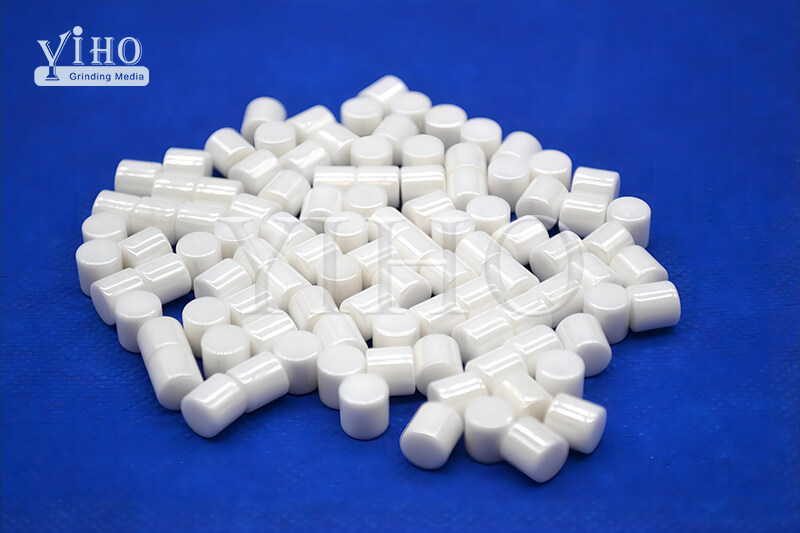

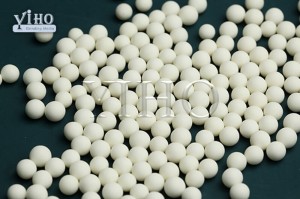

Zirconia (YSZ) Rod cylinder grinding media

Compared with alumina rod Yttria stabilized zirconia (YSZ YTZP) rods could withstand even higher temperature. Zirconia also has better corrosion and wearing resistance. As an extremely refractory material, working temperature of zirconia rods could be as high as 1900C and being stable to most of corrosive chemicals as well. Zirconia crucibles also provide very low thermal and electrical conductivity amking it an ideal for applications requires electrical and thermal insulating

However, unlike boron nitride, Zirconia rod is not recommended to be used as a raw material for further machining work, due to the high hardness and wearing resistance.

Yiho YSZ Rods

As a major supplier of custom advance ceramic materials in east coast USA, QS Advanced Materials is working closely with manufacturers of ceramic sintering and machining capability to provide quality stabilized zirconia products with highly efficient price. We are continuously providing zirconia crucibles and other basic materials. With semi finished stocks, and high production capbalility, advantages in lead time and cost is provided.

Applications of Yttria Stabilized Zirconia (YSZ,YTZP) parts

• Used for grinding ceramics materials, magnetic materials and organic samples

• Bearing and other wear resistance mechanical parts

• Special pump parts

Zirconia ceramics performance

Density:6.05 g/cm3

Water absorption:<0.05%

Firing temperature:1550 °C

Hardness:1350 HV

Compression strength:25000 MPa

Thermal expansion coefficient:9.5x10-6 /°C

Bending strength:950 MPa

Packaging

As a ceramic material, Zirconia material is still brittle, although YSZ is somehow flexible. Our zirconia rods are usually hold in plastic bags by vacuum, and protect with heavy foam.

Properties Sheet

| Properties | Units | 95 Alumina | 99 Alumina | Zirconia |

| Density | ɡ / cm3 | 3.65 | 3.92 | 5.95 - 6.0 |

| Water Absorption | % | 0 | 0 | 0 |

| Coefficient of Thermal Expansion | 10-6 / K | 7.9 | 8.5 | 10.5 |

| HV Hardness | Mpa | 1400 | 1650 | 1300 - 1365 |

| Flexural Strength @ Room Temperature | Mpa | 280 | 310 | 950 |

| Flexural Strength @ 700℃ | Mpa | 220 | 230 | 210 |

| Compressive Strength@Room Temperature | Mpa | 2000 | 2200 | 2000 |

| Fracture Toughness | Mpa * m½ | 3.8 | 4.2 | 10 |

| Heat Conductivity @ Room Temperature | W / m * k | 18 - 25 | 26 - 30 | 2.0 - 2.2 |

| Electrical Resistivity @ Room Temperature | Ω*mm2 / m | >1015 | >1016 | >1015 |

| Max Application Temperature | ℃ | 1500 | 1750 | 1050 |

| Resistance to Acid Alkaline | / | High | High | High |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Thermal Shock Resistance | Δ T ( ℃ ) | 220 | 180 - 200 | 282 - 350 |

| Tensile Strength @ 25℃ | Mpa | 200 | 248 | 252 |