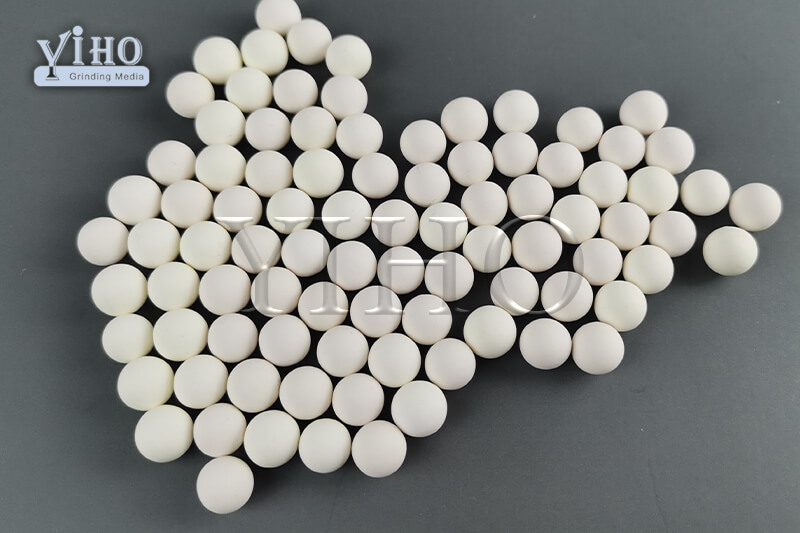

ZTA alumina composite zirconia ceramic grinding media

Improvement and Optimization of Material Performance

ZTA (Zirconia Toughened Alumina) is a composite material made from alumina and zirconia. It combines the outstanding characteristics of both materials.

ZAT ball is made through a ball mill to a certain fineness, spray granulated, and then formed by sintering. It is formed by calcined at high temperature in a tunnel kiln. Its appearance provides an additional choice for customers who pursue high grinding cost performance, and enriches the product line of ceramic grinding balls.

Compared to conventional alumina, ZTA possesses superior hardness, higher flexural strength, and similar density. Compared to conventional zirconia, it possesses a lower coefficient of linear thermal expansion and higher thermal conductivity.

By leveraging these features, ZTA has been widely adopted in milling parts and wear-resistant parts.

ZIRCONIA TOUGHENED ALUMINA BALL Features

High Stiffness and Outstanding Wear ResistanceStiffer than alumina with outstanding wear resistance equivalent to zirconia.

High Thermal Conductivity and Low Thermal ExpansionSuppresses thermal deformation through thermal conductivity and low thermal expansion equivalent to alumina. Suitable for components requiring a cooling Mechanism.

High Strength and Specific RigidityApproximately twice as strong as alumina and contributes to low-weight design through high specific rigidity.

Zirconia Alumina Composite Ball Typical Application

ZTA grinding media, is mainly used in coating, paint, pigment, ceramics, ink, electronic ceramics, titanium dioxide, pesticides, Kaolin, calcium carbonate, zirconia powder, mineral material, special chemical and other industries, also applied in Nano materials(such as lithium battery, barium sulfate, grinding ceramic ink, etc.

Zirconia Alumina Composite Ball Properties

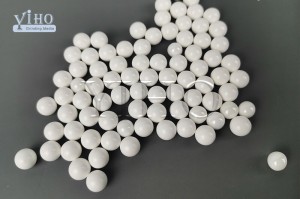

High strength, high fracture toughness, high corrosion resistance and super smooth surface, etc.

Large specific gravity, abrasion resistance, PPM abrasion grade, high hardness.

Zirconia Alumina Composite Ball Chemical Property

|

ZTA370 |

ZTA380 |

ZTA450 |

ZTA470 |

ZTA500 |

|

|

Al2O3(%) |

≥87 |

≥66 |

/ |

/ |

/ |

|

ZrO2(%) |

≥5 |

≥18 |

≥62 |

≥70 |

≥75 |

|

SiO2(%) |

≤5 |

≤12 |

≤30 |

≤24 |

≤20 |

|

HV hardness(GPa) |

≥12.5 |

≥11 |

≥10 |

≥10 |

≥10 |

|

Crushing Strength(N) |

≥1000(ø3) |

≥12000(ø8) |

≥1200(ø3) |

≥1300(ø3) |

≥1450(ø3) |

|

Water absorption |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

<0.01 |

|

Bulk density(g/cm3) |

≥3.7 |

≥3.8 |

≥4.5 |

≥4.70 |

≥5.0 |

|

Wear loss rate(g/kg.h) |

≤1.5 |

≤1.5 |

≤1.3 |

≤1.3 |

≤1.0 |

|

Sphericity |

≥95% |

≥95% |

≥95% |

≥95% |

≥95% |

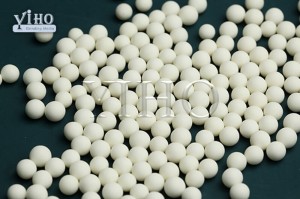

Zirconia Alumina Composite Ball Standard Dimension

ø0.5-1mm, ø1.5mm, ø2mm, ø2.5mm, ø3mm, ø3.5mm, ø4mm, ø5mm, ø6mm, ø8mm. 10mm,13mm

Zirconia Alumina Composite Ball Packing

Different package as to meet different customer’s requirements.

Wooden Crates Drum Plastic Pallet Bulk Packing Plastic Bucket