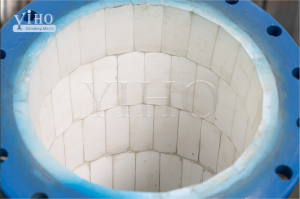

Ceramic lined T pipes with flanges

As wear resistant ceramics lined pipe

supplier, YIHO ceramics can meet customized design and product kinds of alumina ceramic linings for lined steel pipelines. Several ceramic liner pipe wear solutions ways can be offered for client’s options.

Solution 1: Lined with Trapezoidal/pipe tiles with size 150*23/21*20mm, 150*33/27*25mm, or other dimensions per the drawing.

Advantage:Lower cost

Solution 2: Lined with alumina sleeve/tubes&Elbow pipe tiles, with Dia.100-300mm, Length 100-500mm.

Advantage: Easy to Fix & few gaps

Solution 3: Lined with Mosaic lining pieces

Mosaic pieces sizes: 17.5*17.5mm or 20*20mm, Thickness 3-20mm

Advantages: Suitable for Lining the small diameter Steel pipes.

Solution 4: Lined with Silicon Carbide Tube or Tiles,Diameter ranges from 2” to 30”

Advantage: More Abrasion Resistance than Alumina Type, Big Diameter Tube can be easily manufactured.

Benefits using wear resistant ceramics in the Ductwork Linings

• Designed with the same internal diameter as the existing unlined pipe

• Various minimum wall thicknesses are available

• A heavier wall is recommended for optimum wear life

• Segmented cylinders or pipe tiles specifically designed for the pipe size and application

• Easy installation into the steel piping

• Special oversized flanges can be used on existing straight pipes to connect to ceramic lined fittings

• Extensive expertise in material science

• The latest CAD technology

• Unique shaping capabilities

• Custom engineered ceramic shapes available in a pre-fired state

• Precise fit and full ceramic protection throughout the thickness of every joint

• Superior wear system

• Eliminates frequent downtime for repairs

• Substantially extends equipment service life

Why Choose Ceramic Linings ?

Ceramic linings can extend wear life and improve performance when integrated into any transport piping where an abrasive material is being moved, whether this is via gravity feed, dense phase, dilute phase, slurry or vacuum conveying. In industrial environments where highly abrasive materials are pneumatically conveyed, unlined steel or rubber-lined elbows may wear out in a matter of weeks, resulting in an expensive cycle of downtime for frequent repairs and replacements.