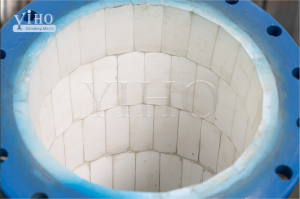

Ceramic Lined Wye Feed Pipe&Tees

Pipe wyes and pipe tees

Pipe wyes are similar to pipe tees. The only difference is in that the branch line is angled to reduce friction which could hamper the flow. The pipe connection is typically at a 45-degree angle rather than a usual 90-degree angle. If a branch turns out at the end to be perpendicular to the through line, the pipe fitting becomes a "tee wye".

Main Properties of Ceramic

|

Category |

HC92 |

HC95 |

HCT95 |

|

Al2O3 |

≥92% |

≥95% |

≥95% |

|

ZrO2 |

/ |

/ |

/ |

|

Density |

≥3.60g/cm3 |

≥3.65g/cm3 |

≥3.70g/cm3 |

|

Water Absorption |

≤0.1% |

≤0.1% |

≤0.1% |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

|

Fracture Toughness KIc MPam 1/2 |

≥3.7 |

≥3.8 |

≥4.0 |

|

Wear Volume |

≤0.25cm3 |

≤0.20cm3 |

≤0.15cm3 |

Characteristics ceramic composite pipe

Good wear resistance

Ceramic composite pipe due to corundum ceramic (a-AL2O3), Mohs hardness of 9.0 is equivalent to more than HRC90. Therefore, it has high wear resistance for abrasive media conveyed by industries such as metallurgy, electric power, mining, and coal. It has been confirmed by industrial operation that its wear life is ten times or even several ten times that of hardened steel.

Small operating resistance

SHS ceramic composite pipe is not like a convex spiral line on the inner surface of a seamless steel pipe because the inner surface is smooth and never corrodes. The inner surface roughness and clear water resistance characteristics of the relevant test units were tested. The smoothness of the inner surface was better than that of any metal pipe. The clear drag coefficient was 0.0193, which was slightly lower than the seamless pipe. Therefore, the tube has the characteristics of small running resistance and can reduce operating costs.

Corrosion, anti-scaling

Since the steel ceramic layer is (a-AL2O3), it is a neutral characteristic. Therefore, it is resistant to acid and alkali and seawater corrosion, and it also has anti-scaling properties.

Temperature resistance and heat resistance

Due to the corundum ceramic (a-AL2O3), it is a single stable crystalline structure. Therefore, the composite pipe can operate normally in the long-term temperature range of -50--700°C. Material linear expansion coefficient of 6-8 × 10-6/0C, about 1/2 of the steel pipe. The material has good thermal stability.

The cost of the project is low

Ceramic composite pipes are light weight and affordable. It is 50% lighter than the cast stone tube with the same inner diameter; it is 20-30% lighter than the wear-resistant alloy tube, and it has good wear resistance and corrosion resistance because of its long service life, thus supporting hanger costs, transportation costs, installation fees, and Reduce operating costs. Comparing the project budget of the design institute and construction unit with the actual project, the project cost is equivalent to the cast stone. Compared with the wear-resistant alloy pipe, the project cost is reduced by about 20%.

Easy installation and construction

Because of its light weight and good welding performance. Therefore, welding, flanges, quick coupling, etc. can be adopted, and the construction and installation are convenient, and the installation cost can be reduced.

Application

Ceramic lined pipe elbows could be also applied in the parts of concrete pump owing to their advantages, especially the low weight, which helps to avoid the jam during the transport of concrete.

Replace carbon steel pipe, stainless steel pipe and SDR

High wear material discharge

Magnetite feed and drain lines

Tailing underflow