High purity oxide alumina ceramic tiles

High purity oxide alumina ceramic tiles Introduction

Yiho premium alumina ceramics are manufactured by blending and mixing specified ratios of high-quality raw materials such as alumina powders, oxides, lubricants, dispersion agents, binders and water using a ball mill method. The slurry then goes through a spray drier before the pressing stage. Low percentages of organic binders allow the alumina particles to bond together and form a green un-sintered body during the pressing stage. Once pressed to size, pre-heating takes place followed by sintering through a tunnel kiln. Sintering temperatures and times are strictly followed to ensure binder burn out is optimized and that explosive spalling does not take place.

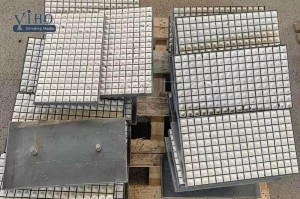

YIHO Ceramic Tile is a preferred liner option in areas of extreme small particulate abrasion with minimal impact. The 90% fine grain, high grade alumina is manufactured to the highest standards, producing a premium product that can hold up to your most abrasive materials. Ceramic tiles offer great mechanical properties with superior sliding abrasion resistance.

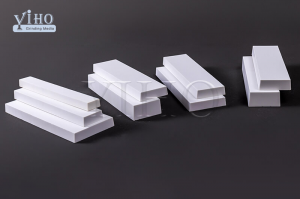

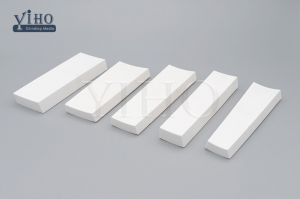

YIHO Ceramic Tiles are offered in several thicknesses to address the requirements of your specific application.

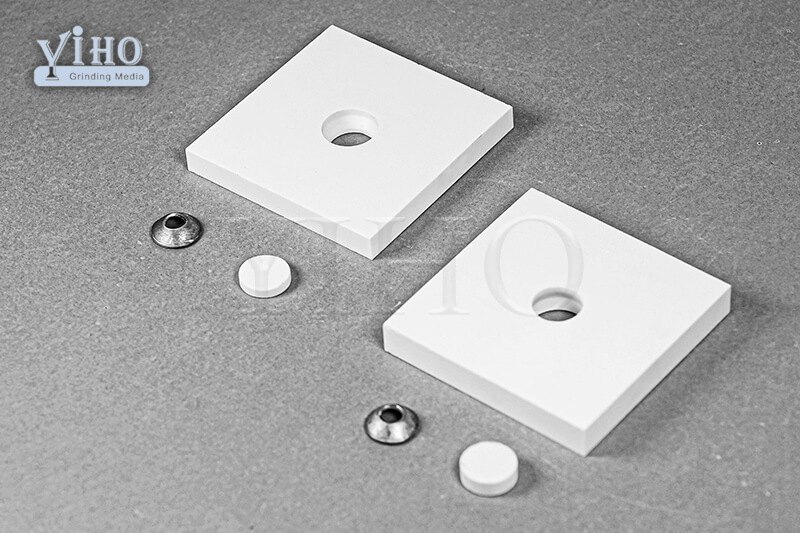

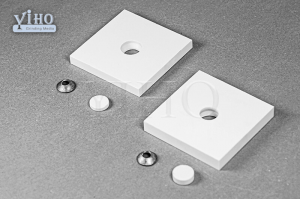

YIHO Tiles are offered with a choice of attachment methods for optimal performance.

High purity oxide alumina ceramic tiles ADVANTAGES

· Greatest Level of Sliding Abrasion Resistance

· Cost Effective

· Multiple Thickness Options

· Chemical Resistance

High purity oxide alumina ceramic tiles

Features

• Pre-engineered shapes

• Abrasion resistance

• Temperature resistance

• Impact resistance

• Hardness and durability

• Corrosion resistance

• Varying grades

• Quality assured

• Usability

Markets

• Coal handling plants

• Steel mills

• Iron ore beneficiation plants

• Hard rock concentrators

• Power generation

• Ports

• Appliances

• Laboratories

• Conveyors

Attachment Options: Epoxy or Weld-on

High purity oxide alumina ceramic tiles STANDARD THICKNESS

STANDARD THICKNESSES

|

Thickness |

1/4″=6mm |

|

1/2″=12mm |

|

|

3/4″=20mm |

|

|

1″ =25mm |

|

|

2″ = 50mm |

|

|

|

3”= 75mm |

High purity oxide alumina ceramic tiles Material Types

|

Composition |

Thicknesses/Diameter |

Type |

| Zirconia Toughened Alumina | 12mm-50mm | Standard tile sizes |

| Alumina 92% / Al203 | 6mm-75mm pre-engineered | Standard tiles, half tiles, pipe tiles, hex mats, pulley lagging tiles, monolithic sleeves, cylinders, cones, tile sets |

| Alumina 95% Al203 | 6mm-75mm | Std tile sizes, half tiles, pipe tiles |

| Reaction Bonded Siliconized Silicon Carbide (RBSiC) | 6-50mm pre-engineered | Std tiles, monolithic sleeve, cylinders, cones, tile sets |