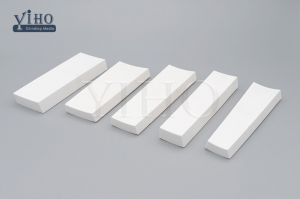

Ceramic Ball mill lining 95% Zirconia Brick

About Zirconia Ball Mill Lining Brick

95% zirconia lining bricks are a type of ceramic brick used in industrial applications such as ball mills, attritors, and vibro-energy grinding mills. These bricks are made of a high-purity zirconium oxide (ZrO2) material with a zirconia content of at least 95%.

Zirconia lining bricks offer excellent wear resistance and are able to withstand high temperatures, making them ideal for use in harsh industrial environments. They are commonly used in the mining, chemical, and pharmaceutical industries, where grinding and milling of materials is a critical part of the production process.

In addition to their excellent wear resistance and thermal stability, zirconia lining bricks also offer good corrosion resistance and are chemically inert, making them suitable for use with a wide range of chemicals and materials.

Overall, 95% zirconia lining bricks are a high-performance material that can improve the efficiency and longevity of industrial grinding equipment, leading to cost savings and increased productivity.

Zirconia Ball Mill Lining Brick Technical Data

|

ZIRCONIA LINING BRICK |

||

|

ITEMS |

Typical Values |

|

|

Composition |

Wt% |

94.8% ZrO2 |

|

|

|

5.2% Y2O3 |

|

Density |

g/cm3 |

≥6 |

|

Hardness (HV20) |

GPa |

≥11 |

|

Bending Strength |

MPa |

≥800 |

|

Fracture Toughness |

MPa.m1/2 |

≥7 |

|

Rock Hardness |

HRA |

≥88 |

|

Wear Rate |

cm3 |

≤0.05 |

|

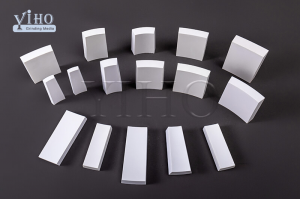

Specification |

|

Customized |

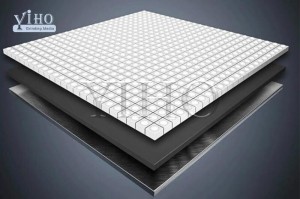

Why Choose Zirconia Brick?

Instead of using metal, use these zirconia ceramic sheets to make wear pads, guides, barriers, and other parts that must resist bending and wear while maintaining strength under heavy loads. The addition of yttria increases strength and lowers the chances of cracking from impact compared to standard zirconia, alumina, and silicon nitride ceramic. If cracks do occur, they will not spread, so the material remains durable and long-lasting. Added yttria also means this material resists wearing down from rubbing against another part or abrasion from chemical slurries.

While this material resists bending better than other high-performance ceramics like alumina and silicon nitride, it does not withstand rapid temperature changes or high temperatures as well.

Zirconia Ball Mill Brick Project Case