Conveyor Chute Lining Impact Liner Panel

Chute Linings are designed to be an integral part of a conveyor system. Our pre-engineered chute lining protects and cushions the chute from the material being handled; Skirt Liners prevents fugitive materials from escaping and damaging the conveyor loading areas. We can build, design, fabricate and install chutes, and also repair and re-align existing chutes.

Combining the right liner with the correct chute design improves overall system efficiency and maximizes material transfer, promoting efficient flow, dust suppression and reduced buildup inside the chute.

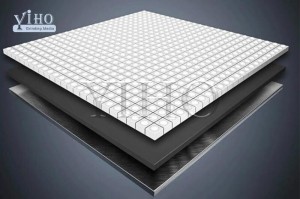

Ceramic Materials

92 %, 95%, 99% -Al2O3 ceramic tiles (Cylinder, square, rectangular or

hexagonal „SW“) vulcanized in special rubber with CN bonding layer.

|

Al2O3 |

SiO2 |

CaO |

MgO |

Na2O |

|||

|

92%~99% |

3~6% |

1~1.6% |

0.2~0.8% |

0.1% |

|||

| Specific gravity (g/cc) |

>3.60 |

>3.65 |

>3.70 |

||||

| Apparent porosity (%) |

0 |

0 |

0 |

||||

| Bending Strength (20℃, Mpa) |

220 |

250 |

300 |

||||

| Compressive strength (20℃, Mpa) |

1050 |

1300 |

1600 |

||||

| Rockwell hardness (HRA) |

82 |

85 |

88 |

||||

| Vickers hardness (HV20) |

1050 |

1150 |

1200 |

||||

| Moh’s hardness (scale) |

≥9 |

≥9 |

≥9 |

||||

| Thermal Expansion (20-800℃, x10-6/℃) |

8 |

8 |

8 |

||||

| Abrasion Loss (Cm3) |

0.25 |

0.2 |

0.15 |

||||

Ceramic Conveyor Liner Properties

• CN bonding layer provides fast and long lasting adhesion

• Highest abrasion resistance

• Reduces operating costs

• Long service life increases the efficiency of the equipment

• Good resistance against weather

Area of application of Ceramic Rubber Liner

Wear Solutions has particular experience in the use of a diverse range of lining materials such as Basalt, Alumina, Silicon Carbide, polyurethane and quarry tiles. Vessels and plant items include transfer chutes, launders, and cyclones, etc.

• Lining against extreme wear through abrasion at high speeds

• For simple to medium duty applications in mining, gravel, sand and stone breaking mills and other industrial sectors

• In applications like pipelines, vibratory feeders, cyclones, skips, bunkers, chutes, loading points, slides, hoppers, silos