Rubber backed&Composite ceramic liners

-

Ceramic sleeve lined pipe fittings applied in mining industry

The big diameter ceramic sleeve is always a big problem for the ceramic tube manufacturers since it’s very difficult to control the deformation rate of the ceramic sleeve after it’s sintering .Also It will also need an advanced and big isostatic pressing machine to do this .So it will not only express the company’s production capability ,but company’s technology. Right now, our factory have owned both advantages which are wear resistant ceramic pressing facilities and technologies.

-

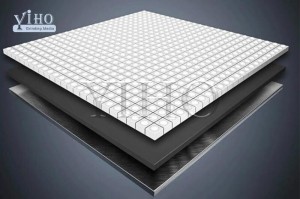

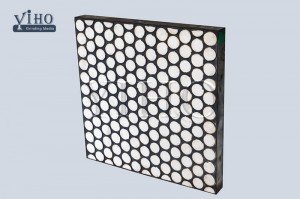

HEAVY WEAR PROTECTION Ceramic/rubber lining material

Ceramic composite rubber lining backed steel plate is the liner vulcanizing the ceramic and rubber into the steel plate. It can be connect with bolts and nuts or by welding the steel plate to do the connections. This product is normally the customized products, it can be made with different shapes, different thickness according to the working conditions.

-

Ceramic lined flexible rubber hoses

Ceramic tiles or Ceramic Balls are embedded into the inner tube of the Performer Ceramic hose. The ceramic material has been selected for its excellent abrasion resistance and allows at least 10 times longer lifespan compared to a rubber hose.

-

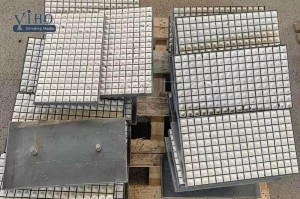

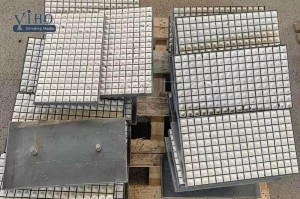

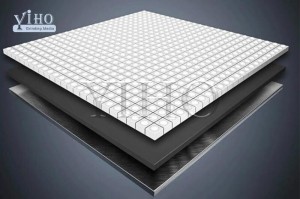

2 in1 or 3 in 1 Composite Ceramic Wear Plate

Composite ceramic rubber wear plate.

Excellent wear resistance, wear life of high alumina ceramic is approx. 5 timers longer than rubber and 10 times longer than steel.

More impact resistant, rubber or polyurethane cushions makes more impact resistant.

Available in irregular shapes and sizes.

-

Ceramic wear plates for aggressive abrasion

Ceramic wear plate is used in truly aggressive environments where heavy flows of rough materials causes impact and strain on the equipment. Ceramic wear plate contributes to better abrasion resistance, higher payload and much longer service life.

-

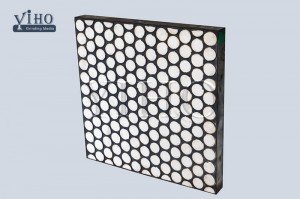

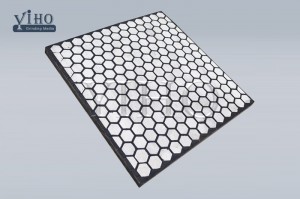

RUBBER-CERAMIC WEAR LINERS

The majority of our wear liners are designed for use in the process plant, power generation and material handlings industries. Wear lining materials used include ceramic linings, ceramic composites, rubber wear plates that include ball mill liners and profile liners among many others, basalt linings, epoxy wear compounds

wear liner solutions protect your materials handling chutes, bins and tanks and improve the flow of material through your plant. Our installation teams undertake complete installation of your wear liners and provide assistance and/or supervision when required.

-

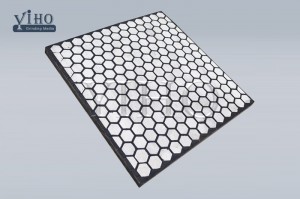

Wear resistant steel-rubber-ceramic panel vulcanized ceramic plates

In aggressive industrial applications, equipment where high impact , high abrasion inevitably suffer mechanical attack, chemical attack, corrosion, or by a combination of these three modes.

YIHO’s Ceramics can offer various of ceramic liner plate for customer’s abrading environment. Composite ceramic wear liner is intended for the toughest applications with very high materials. when a combination of extreme wear and impact resistance ans long wear life is needed , Ultraming offer composite ceramic wear liner with large and hard ceramic bricks vulcanized into a matrix of wear resistant rubber .due to its elastic properties the rubber acts as a dampener. It makes it possible to use this product in applications with a lot of impact without the risk of crushing the ceramic bricks .

-

CERAMIC CLINDER FOR EXTREME WEAR PROTECTION

Mineral Processing equipment operates in some of the harshest and remote locations. It is crucial to the Mineral Processing industries that this equipment continues to operate efficiently and its life cycle is maximized to minimize down time. By appropriately protecting equipment from the extreme wear caused by the high speed and flow rates of ore when processed as a slurry ensures better equipment longevity. Slurry is highly abrasive and can not only cause wear damage to wet processing equipment but also with the inclusion of chemicals and heat, there is constant risk of corrosion and dangerous leakage.

-

Abrasion& Anti impact Ceramic Skirting Canoe Liners

Keeping product on the line and off of adjacent walkways and equipment is critical to maintaining a safe and productive work environment. Our tough skirting liners are available in solid rubber or a combination rubber/ceramic matrix, our high wearing skirt liners keep ore in line and protect your equipment, saving time and money while increasing production. Handy Tee slot mounting allows for use in skirting or solid wall wear applications and are interchangeable.

-

Wear-resistant ceramic bonding steel plate

The Wear-resistant ceramic bonding steel plate is to directly bond the toughened wear-resistant ceramic with a high-strength organic adhesive or an inorganic adhesive with a maximum temperature of 350 ℃ directly into the steel plate, and is used as an anti-wear lining for material conveying equipment in room temperature environments.