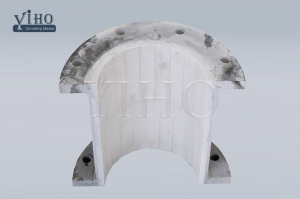

Wear Resistant Cyclone Lining Tube Made from Alumina

Relevant technical introduction of wear-resistant ceramic Tube

The wear resistant ceramic Tube is a special kind of ceramic with Al2O3 as the main raw material and the rare metal oxide as the flux, which is melted by high temperature at 1700 ℃.

Advantages of Cyclone Lining Tube

1. Exceptional wear resistance: The ceramic material used for the sleeve provides excellent resistance against wear and abrasion caused by abrasive media, improving the lifespan of the piping system.

2. Corrosion resistance: Ceramic materials are highly resistant to corrosion, making them ideal for use in corrosive environments.

3. High-temperature resistance: Ceramic sleeves can withstand high temperatures without losing their mechanical properties, making them ideal for use in high-temperature applications.

4. Reduced friction and turbulence: The smooth surface of the ceramic pipe sleeves reduces friction and turbulence, resulting in reduced pressure loss and increased flow rates.

5. Improved safety and reliability: Ceramic sleeves/Tube can significantly reduce the likelihood of equipment failure, enhancing the safety and reliability of industrial operations.

6. Easy installation: Ceramic sleeves are easy to install and can be tailored to fit specific sizes and shapes required by the application.

Technical Data of Alumina Ceramic Linings

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

HC-ZTA |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

≥75% |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥21% |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

>4.10 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1350 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥90 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥400 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

≥2000 |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥4.5 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

≤0.05 |

Cyclone Components Commonly Subject to Wear

There are many components within a cyclone assembly that are subject to high wear conditions. Taylor Ceramic Engineering can supply many of these in wear resistant materials to extend component life. Some of the parts that we typically supply include:

• Cylindrical & Reducing Liners

• Inlets

• Outlets

• Spigots

• Inserts

• Upper, Mid & Lower Cone Sections

• Vortex finders

• Virtually any surface that undergoes wear!

Material of Cyclone Linings

1. Alumina

2. RBSiC silicon carbide

3. ZTA

Dimensions can be customized by client’s request

Apart from the standard alumina ceramic tile, we can also manufacturer the pre-engineering ceramics to suit different equipment. Product Introduction: Separator cyclone equipment is mainly abrasive damaged by handling material, YIHO can design ceramic cyclone liners according to customer's cyclone size and wear resistance requirement. ceramic tile liner cut and then composed . Product Application: Apart from the standard alumina ceramic tile, we can also manufacturer the pre-engineering ceramics to suit different equipment. We have our technical team who can help the client to choose the suitable wear resistant ceramic products ,and also we have the ability to design and make the CAD drawings according to the client’s wear application. The Tailor-made ceramics had the advantage of low wear, high hardness and impact resistance , it widely used for the chutes, hoppers, bunkers , pipelines in the mining, power generation, steel plant, steel plant industries, it make cost effective performance and reduce the maintenance cost and down-time for the clients