Mining Wear Ceramic Lined Part and Components

Wear Resistant Ceramic Lined Parts and Components

Ceramic Lining Pipe and Elbow have very uniform coating of specially formulated ceramic material that is affixed to the inner of the pipe and gives a very smooth surface. Ceramics with very low friction factor at low impingement angles decreases the abrasion of materials maximally. Its low density makes it easy to carry and install. Furthermore, its diamond-like hardness, fine grain structure and superior mechanical strength are the unique features that make it a wide range of demanding applications, such as coal preparation, power generation, iron and steelmaking, cement, asphalt, dredging, mining and mineral processing, oil and gas drilling.

Metals have good ductility but poor resistance to abrasion - which means that abrasion prevention is required when metal pipes are used in high-temperature fluid catalyst service. On the other hand, ceramics possess great hardness and abrasion resistance, but they are brittle. Metal Ceramic double pipe is a hybrid pipe using metal as an outer pipe and a ceramic material for inner pipe segments, applied together to utilize the two materials' advantages. Hence excellent wear-resistance and good corrosion resistance of the ceramics and high strength and toughness of metal can be well combined to get a comprehensive advantage of wear-resistance, corrosion-resistance and anti-scaling. They are suitable for applications in heavy wear working conditions.

Ceramics are among the hardest materials available and provide ultimate wear resistance in piping. In high wear applications, ceramic lined pipes have been demonstrated to be cost-effective by increasing service life and reducing maintenance costs. Sunny Steel supply ceramic lined abrasion resistant steel pipes to your custom dimensions and budget. Our ceramic linings are the highest quality materials available to ensure that we provide the most cost-effective solutions for our clients.

The Ceramic Tiles could protect Industrial Components against abrasion, impact wear and high temperature of above 1000°C. Standard Flat Tiles of Square & Rectangular Shape having thickness of 6 to 50 mm, with or without central hole are available.

Materials: seamless mild steel pipe plus 92% or 95% alumina, and Silicon Carbide ceramics for liner

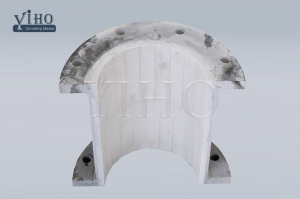

YIHO can supply Liners are generally composed of

Silicon Carbide

Alumina or

composite ceramic Liner

In situations where ceramic materials may not be suitable, we also supply linings made from:

Polyurethane or

Rubberw

Ceramic Pipe Linings

Our ceramic pipe linings have been used in very abrasive environments.

They are produced from high purity (92% or 99%), high density Alumina.

They exhibit around 8 - 10 times the wear life of comparative materials, ie steels, rubbers and polyurethanes.

We stock various straight and elbow sections and can tailor to your needs.

Benefits of Ceramic Wear Parts

The benefits of technical advanced ceramic wear parts, components and products include stronger materials, corrosion resistance, thermal protection and longer life expectancy.

Industries Served

• Power Industry (Coal fired & Biomass)

• Coal Mine and Preparation Plants

• Cement & Asphalt Processing

• Pulp & Paper Mills

• Water & Waste Water Treatment

• Mineral Processing

• Steel Industry