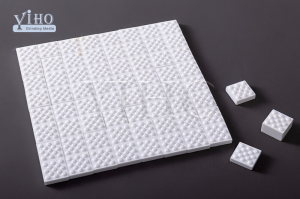

Abrasive Materials Wear-Resistant Alumina Ceramic Ball Mill Lining Brick

Alumina Ceramic Ball Mill Lining Brick Introduction

Alumina ceramic ball mill lining bricks are used to line the inner shell of ball mills, thereby protecting the steel shell from the abrasive and often harsh conditions of the milling process. These bricks are made from high-quality alumina ceramic materials, which have excellent mechanical properties such as high hardness, wear resistance, and impact resistance.

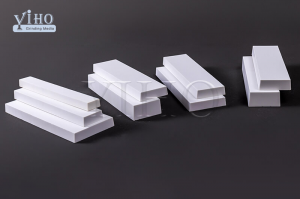

Dimensions and Weights of Standard Size Mill Lining Brick

|

Name |

Length (mm) |

Width 1 (mm) |

Width 2 (mm) |

Thickness(mm) |

|

|

40~90mm Thickness Lining Brick |

Rectangular Brick |

150±2 |

50±1 |

50±1 |

40/50/60/70/77/90±1 |

|

|

Trapezoidal Brick |

150±2 |

50±1 |

45±1 |

40/50/60/70/77/90±1 |

|

|

Half Rectangular Brick |

75±1 |

50±1 |

50±1 |

40/50/60/70/77/90±1 |

|

|

Half Trapezoidal Brick |

75±1 |

50±1 |

45±1 |

40/50/60/70/77/90±1 |

|

|

Flake Brick |

150±2 |

25±1 |

22.5±1 |

40/50/60/70/77/90±1 |

|

Special Specification Lining Bricks |

80x50x55 |

55±2 |

50±1 |

50±1 |

80±1 |

|

|

110mm Ling Brick |

75±1 |

45±1 |

41±1 |

110±2 |

|

|

110mm Half Ling Brick |

37.5±1 |

45±1 |

41±1 |

110±2 |

|

|

Brick for Manhole and Drain-hole |

The specification can make according to the customers' requirements. |

|||

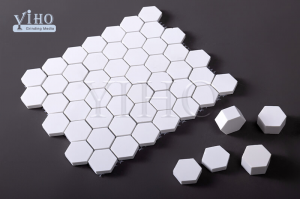

Alumina Ceramic Ball Mill Lining Brick Application

Widely used in power plants, steel mills, chemical, rubber, and coating fields, is the ideal surface wear-resisting material for material transfer equipment in mining, iron & steel works, thermal &powder plants, mine, etc, also used in ceramic, glaze, paint, zirconium silicate, alumina oxide, quartz, silicon carbide, lime carbonate, and mechanical equipment accessories, can extend the operating life effectively.

Theoretically the life time of the alumina ceramic is about 260 times longer than that of manganese steel and 170 times longer than that of chrome steel.

Alumina Ceramic Ball Mill Lining Brick Property

High density, high hardness, low wear loss, regular shape, impact resistance, corrosion resistance, etc.

Alumina Ceramic Ball Mill Lining Brick Technical Data

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

ZrO2 |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

/ |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥95% |

|

Density |

>3.60g/cm3 |

>3.65g/cm3 |

>3.70g/cm3 |

>3.83g/cm3 |

>5.90g/cm3 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1100 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥88 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥800 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

/ |

|

Fracture Toughness KIc MPam 1/2 |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥7.0 |

|

Wear Volume |

≤0.25cm3 |

≤0.20cm3 |

≤0.15cm3 |

≤0.10 cm3 |

≤0.02cm3 |

Alumina Ceramic Ball Mill Lining Brick Packing

Different package as to meet different customer’s requirements.

Wooden Crates | carton on Plastic Pallet

Alumina Ceramic Ball Mill Lining Brick Application

* Ceramic complex pipeline of glass fiber reinforced plastics,

* Alumina ceramic liner for cement cyclone,

* Metal complex pipeline and elbow,

* Abrasive liner for down spouting,

* Abrasive liner for pipeline,

* Preheater bracket,

* Abrasive wheel of powder.