Ceramic pulley lagging tiles

Introduction of Ceramic Pulley Lagging Tiles

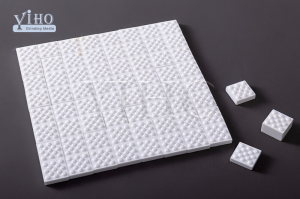

Ceramic pulley lagging is a reliable solution for belt slippage problems, that conventional rubber lagging often cannot correct. In fact, it features the highest co-efficient of friction available in lagging materials which may be two to three times the friction of rubber in wet, muddy or dry conditions. Yiho ceramic pulley lagging is constructed from hundreds of individual ceramic tiles moulded in to a durable rubber backing.

The rubber-ceramic lining of pulley is particularly suitable in cases where slippage and excessive wear make normal rubber lining ineffective. Alumina ceramics tiles allow to maintain the correct position of the belt, even in conditions of high humidity, heavy pollution and abrasive impact. Also, by varying the thickness of the ceramic elements and the total thickness of the lining, it is possible to compensate the difference in diameters of the pulleys

A. Rubber

1. Material: NR&BR

2. Density: 1.15 g/sm

3. Tensile strength: 24 MPa

4. Shore hardness: 60±5

5. Elongation: 360%

6. Wear lost: 85 mm3

7. Ageing coefficient: 0.87 (70C°x48 hours)

B. Alumina ceramics

1. Material: Al2O3 92-95%

2. Density: 3.6 g/cm3

3. Colour: wight

4. Wear lost:<0.20cm3

5. Hardness: Mohs 9

Ceramic Pulley Lagging Tiles Features

• Excellent wear and abrasion resistance, resulting in 20 times (approx) more life than conventional lagging.

• Excellent traction-eliminating belt slippage problems.

• Higher friction value-allows lower belt tension resulting in increased life of conveyor belt and conveyor components such as bearings, pulleys, rollers etc.

• Reduced power consumption due to less tension load on pulleys.

• Positive grip maintained with the conveyor belt, helps to eliminate damage of belt edges.

• Even in wet and muddy conditions the exclusive raised oval design gives positive grip.

• Easy to handle and use.

• Suits a wide range of pulley widths.

• Can be tested on site.

• Can be used for above surface or below ground applications.

• Drastic reduction in down time and production loss.

• One time investment for long life.