Ceramic cyclone parts alumina Cone, Spigot, Apex

Ceramic cyclone parts alumina Cone, Spigot, Apex

Cyclone Components Commonly Subject to Wear

There are many components within a cyclone assembly that are subject to high wear conditions. Taylor Ceramic Engineering can supply many of these in wear resistant materials to extend component life. Some of the parts that we typically supply include:

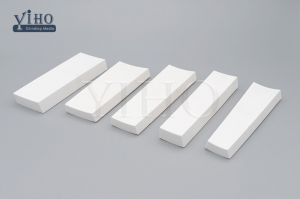

• Cylindrical & Reducing Liners

• Inlets

• Outlets

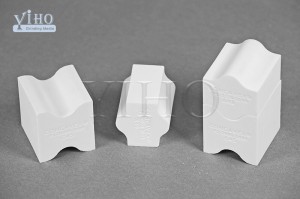

• Spigots

• Inserts

• Upper, Mid & Lower Cone Sections

• Vortex finders

• Virtually any surface that undergoes wear

The material cyclone suffered serious abrasion and impact when it separated the material particle, like coal, gold, iron and ext. because of high speed material conveying. It’s very easy to wear out to leak the material from cyclone and a suitable wear protection solution for material cyclone is very necessary.

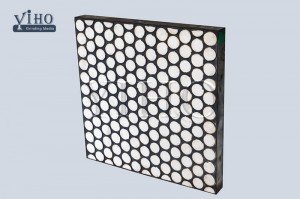

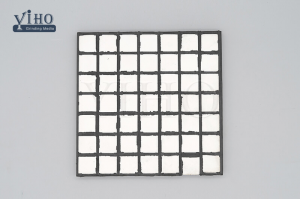

Yiho uses the ceramic liners lined into the inner wall of the cyclone to get the wear & impact protections. It has been turned out it’s a very good wear solution for material cyclones.

Yiho supplies both the complete assembly of the hydro cylone and the high wear areas including the bottom apex and spigots. Cone liners, vortex finders and feed chamber are precision cast for replacement assembly into your existing hydro cyclone.

Also, Yiho can design different shape and thickness ceramic liners for the cyclones according to different working conditions. Custom monolithic cyclone can be manufactured according to client’s drawing.

Material of Ceramic cyclone parts alumina Cone, Spigot, Apex application

Reaction Bonded Silicon Carbide Data (RBSiC)

| Main technical parameters | |||||

| Density(g/cm3) | Porosity Rate(%) | Bending Strength(MPa) | Moh’s Hardness | Corrosion resistance | Working Temperature(℃) |

| ≥3.02 | ≤0.1 | ≥250 | 13 | excellent | ≤1380 |

92%, 95%, 99% Alumina Data

| Main technical parameters | |||||

| Density(g/cm3) | Porosity Rate(%) | Bending Strength(MPa) | Moh’s Hardness | Corrosion resistance | Working Temperature(℃) |

| 3.6~3.9 | ≤0.1 | 220~330 | 9 | excellent | ≤ 800 |

Ceramic cyclone parts alumina Cone, Spigot, Apex Feature& Benefits

• A diverse portfolio of ceramic materials for different types of wear in the cyclone

• Extensive experience in lining design and applications

• Comprehensive ceramic shaping capabilities

Ceramic cyclone parts alumina Cone, Spigot, Apex application Industries

• Hydrocyclones

• Cyclone separators

In Coal, Mining, Cement, Chemical and steel industries .