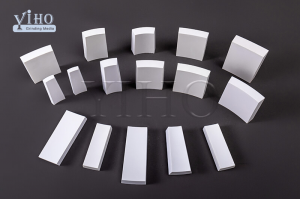

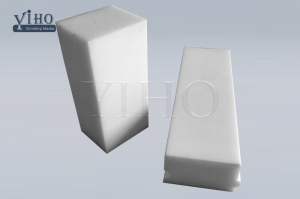

Alumina Wear Resistant Liner Pieces for Pulley Lagging Ceramics

Alumina Pulley Lagging Tiles Detailed description

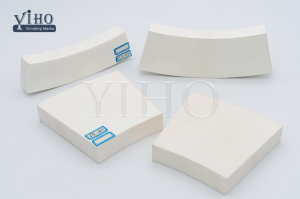

YIHO Pulley lagging is made through hundreds of individual ceramic lining pieces vulcanized into durable rubber plates, every applied ceramic lining tile have raised dimples for abrasion resistance.Generally,with the conveying pressure , thousands of salient point in alumina ceramic liner tile can have a positive traction to prevent slipping, extending the life of the roller conveyor.

Which makes the drive roller life ten times more than the original drum .At the same time,each ceramic sheet has grooves spaced in a certain distance, enabling foreign matter like dust, dirt on the drum discharged along the trench, which makes the drum with a unique self-cleaning function, especially suitable for wet working environment.Alumina ceramic mosaic tile have various sizes available.

Alumina ceramic characters

High alumina ceramic tiles are useful in the bulk material movement, involving sliding and shear interactions, of abrasive materials causes heavy wear to the equipment. This in turn results in damage to the equipment, lower reliability, production losses and lower capacity utilization. Ceramic tiles is a cost-effective and reliable solution and a necessity in today’s competitive world. Our advanced technical ceramics offer higher strength and corrosion resistance than traditional wear materials. High temperature mechanical properties and good to excellent corrosion resistance are the key highlights

> High hardness with Moh's hardness 9 grade

> High abrasion and chemical resistance

> Special dumps designed for more wear resistance

> Light weight with various sizes

Alumina Pulley Lagging Tiles General Properties

Ceramic pulley lagging ensures continuous system operations and optimum drive traction. Ceramic lagging also effectively removes any fine material buildup from extreme operating conditions.

• Improves belt traction, eliminates slippage

• Increases belt and pulley life

• Offers exceptional wear and abrasion resistance

• Installs easily

• Minimize system downtime

• Helps lower your cost per ton for moving material

Alumina ceramic Technical Data

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

|

ZrO2 |

/ |

/ |

/ |

/ |

|

Density(gr/cm3) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |