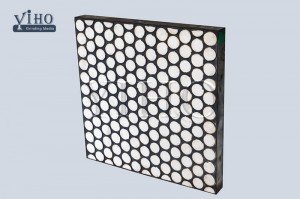

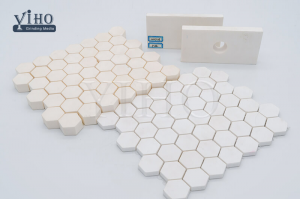

Silicon carbide Tile Block

Silicon carbide wear lining tiles/block Introduction

Silicon carbide RBSC liner, is a kind of new wear-resistant material, the lining material with high hardness, abrasion resistance and impact resistance, high temperature resistance, acid and alkali resistance, corrosion resistance and other characteristics, the actual service life is 6 times more than Alumina lining. Especially suitable for highly abrasive, coarse particles in the classification, concentration, dehydration and other operations and it has been successfully applied in many mine.

Inner Lining and Blocks for Industry Maintenance

SiSiC: Moh’s hardness is 9.5 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. It is 4 to 5 times stronger than nitride bonded silicon carbide. The service life is 5 to 7 times longer than alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. Wear resistant ceramic lining is conductive to make improvement of the production performance, the working efficiency, the reduction of maintenance costs and the increase profits.

- Excellent wear and abrasion protection property.

- Excellent corrosion resistance property

- Excellent heat resistance property

- Excellent impact resistance property

- Excellent for ballistic protection

Wear Resistant Silicon Carbide Ceramic Tiles & Lining Benefits

-- Chemical resistant

-- Electrically insulative

-- Mechanical erosion & Abrasion resistant

-- Replaceable

Silicon carbide wear lining tiles/block Applications

- Mining

- Mineral processing (mineral beneficiation)

- Power generation

- Cement

- Petro-Chemical Refining and Production

- Coal washery

- Steel

- Defense (personal & vehicle armour).

Silicon carbide wear lining tiles/block Specifications

|

Item |

Unit |

Data |

|

Temperature of application |

℃ |

1380℃ |

|

Density |

G/cm3 |

>3.05 |

|

Open porosity |

% |

<0.1 |

|

Bending strength -A |

Mpa |

250 (20℃) |

|

Bending strength -B |

MPa |

280 (1200℃ ) |

|

Modulus of elasticity-A |

GPa |

330(20℃) |

|

Modulus of elasticity -B |

GPa |

300 ( 1200℃ ) |

|

Thermal conductivity |

W/m.k |

45 (1200℃ ) |

|

Coefficient of thermal expansion |

K-1 ×10-6 |

4.5 |

|

Rigidity |

/ |

13 |

|

Acid-proof alkaline |

/ |

excellent |

Silicon carbide wear lining tiles/block Available Shape and Sizes

Thickness: from 6mm up to 50mm

Regular Shape: SiSiC tiles, SiSiC Pipe tiles, SiSiC Three Links, SiSiC Elbow, SiSiC Cone Cyclone.

Remark: Other sizes and shape are available upon requests.

Silicon carbide wear lining tiles/block Packing

Packed in Ply-wooden crate.