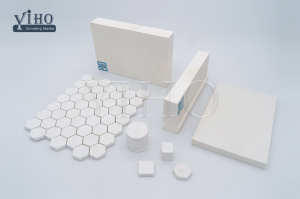

Ceramic Hexagonal wear tile mats

YIHO manufactures a full range of high-density, fine-grain, wear-resistant alumina ceramic hex mats (hexagonal tiles). Our alumina ceramic is next to diamond in hardness, is 12 times more wear-resistant than carbon steel, and exhibits excellent corrosion resistance.

Wear-resistant hex mats prevent erosion and abrasive wear in conveying and bulk material handling systems. Their flexible design allows for lining of intricate systems including fan blades, chutes, hoppers, and more.

Order quantities may range from one box of 10 mats up to container loads.

Size Range of Hexagonal wear tile mats

Tile Thickness Range: 3mm, 6.3mm, 7mm, 8mm, 10mm, 12mm, 15mm, 20mm, 25.4mm

Mat Size Range: 150x150, 250x250, 300x500, 500x500 mm

Technical Specifications of Hexagonal wear tile mats

Ceramic Material: 92%, 95%,99%, ZTA, Silicon Carbide

Surface Finish: White/Black

Dimensional Tolerance: ±1%

Maximum Temperature Limit: 1,500° C

FEATURES & BENEFITS

• High resistance to wear and smooth surfaces

• Corrosion resistance

• Usable in locations subject to chemical stresses

• FDA approved

• Easy to adapt to geometrically complex surfaces

• Operational temperature max.1200°C (depending on conditions for installation)

• Small thicknesses of as little as 1.5 mm upwards

• Weight-saving solution

Long-Lasting Wear Protection

• Ceramic Mats are suitable for all segments, particularly the lining of separators, bunkers, chutes, conveyor belt transfer points, concrete mixers, or cyclones.

• Available for delivery as plates, specially shaped components and cylinders in various formats with differing thicknesses. Installation commonly involves an economic combination of other materials bonded in adhesive or attachment to the plant mechanically on sit

Yiho offer standard tiles and shapes in 92% alumina, 95%, 99% Alumina and RBSiC Silicon Carbide to maximise the wear resistance and increase the operating life in your equipment.

Yiho high density Ceramic Alumina Tiles can be used in conjunction with the following shapes

• Straight spools

• Y spools

• T spools

• Elbows/bends

• Reducers

• Chutes

Yiho standard Ceramic Alumina Tile wear solutions product offering includes:

• Rectangular tiles (plain Tile)

• Pipe tiles

• Weld-On tiles

• Hexagonal tiles

• Square Tiles

• Cylinder

• Cubo