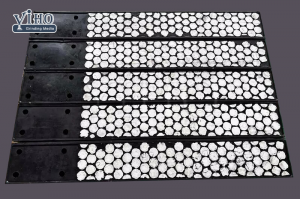

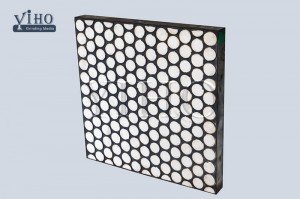

Coal Mining Ceramic Perforated Lining Plate Weldable Tile

Ceramic Perforated Lining Plate Weldable Tile Introduction

YIHO supply and install a wide range of Alumina Wear Resistant Tiles for wear protection of all areas such as Chutes, Silos, Feeders, Bins, Launders, Dutching, Tanks, Bunkers, Hoppers, Underpans etc.

Described as the material of the future, alumina ceramics is one of the hardest of all natural substances known to man. Under extremely abrasive conditions, no material can compete on a cost to life basis with it's extreme hardness and wear resistance. In addition, alumina ceramics has exceptional chemical, mechanical, thermal and electrical insulation properties and can be formed into any shape or size with various qualities for specific applications.

Weld-On alumina ceramic tiles are typically used in high temperature applications and are available in most sizes to suit your application on an ex-stock basis.

Ceramic Perforated Lining Plate Weldable Tile Technical Data

|

Category |

HC92 |

HC95 |

HCT95 |

HC99 |

HC-ZTA |

ZrO2 |

|

Al2O3 |

≥92% |

≥95% |

≥ 95% |

≥ 99% |

≥75% |

/ |

|

ZrO2 |

/ |

/ |

/ |

/ |

≥21% |

≥95% |

|

Density (g/ cm3 ) |

>3.60 |

>3.65g |

>3.70 |

>3.83 |

>4.10 |

>5.90 |

|

HV 20 |

≥950 |

≥1000 |

≥1100 |

≥1200 |

≥1350 |

≥1100 |

|

Rock Hardness HRA |

≥82 |

≥85 |

≥88 |

≥90 |

≥90 |

≥88 |

|

Bending Strength MPa |

≥220 |

≥250 |

≥300 |

≥330 |

≥400 |

≥800 |

|

Compression strength MPa |

≥1050 |

≥1300 |

≥1600 |

≥1800 |

≥2000 |

/ |

|

Fracture Toughness (KIc MPam 1/2) |

≥3.7 |

≥3.8 |

≥4.0 |

≥4.2 |

≥4.5 |

≥7.0 |

|

Wear Volume (cm3) |

≤0.25 |

≤0.20 |

≤0.15 |

≤0.10 |

≤0.05 |

≤0.02 |

Ceramic Perforated Lining Plate Weldable Tile Advantages

Alumina weldable tiles, also known as alumina ceramic weld-on tiles or ceramic weldable linings, offer several advantages when used in wear-resistant applications. These tiles are commonly used to protect industrial equipment and surfaces from abrasion, impact, and wear. Here are some of the key advantages of alumina weldable tiles:

1. High Hardness and Wear Resistance: Alumina ceramic is one of the hardest materials, providing excellent wear resistance and durability. Weldable tiles made of alumina are ideal for protecting equipment and surfaces exposed to abrasive materials.

2. Chemical and Corrosion Resistance: Alumina is chemically inert and highly resistant to corrosive substances, making it suitable for use in industries with aggressive chemical environments.

3. Temperature Resistance: Alumina weldable tiles can withstand high temperatures without significant degradation in their properties, making them suitable for applications involving elevated temperatures or thermal shock.

4. Uniform Surface: The tiles provide a smooth and uniform surface, reducing material build-up and ensuring consistent material flow, which is crucial for certain industrial processes.

5. Ease of Installation: As the name suggests, weldable tiles are designed for easy installation using welding techniques. This allows for quick and secure attachment to the substrate, reducing downtime during installation and maintenance.

6. Customizable Shapes and Sizes: Alumina weldable tiles can be manufactured in various shapes and sizes to fit specific equipment or surfaces, providing flexibility in design and ensuring complete coverage of wear-prone areas.

7. Reduced Maintenance Downtime: By protecting the underlying equipment from wear and damage, alumina weldable tiles extend the operational life of the equipment, reducing the frequency of maintenance and downtime.

8. Cost-Effective: While alumina weldable tiles may have a higher initial cost compared to some materials, their long lifespan and reduced maintenance needs make them cost-effective in the long run.

9. Electrically Insulating: Alumina is an excellent electrical insulator, making it suitable for applications where electrical conductivity needs to be avoided.

10. Compatibility with Various Substrates: Alumina weldable tiles can be used on various substrates, including steel, concrete, and other materials, making them versatile for a wide range of industrial applications.

Overall, alumina weldable tiles offer a reliable and effective solution for wear-resistant applications, providing protection against abrasion, impact, and chemical attack. Their durability, ease of installation, and long-term cost-effectiveness make them a popular choice in industries such as mining, cement, steel, power generation, and material handling, where wear and tear are common challenges.