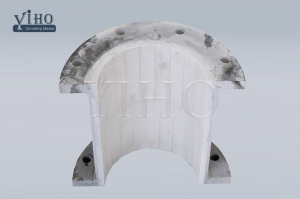

RBSiC Lined Cyclone part for Cyclone & Hydrocyclone Applications

Introduction of RBSiC line Cyclone

RBSiC ( SiSiC ) silicon carbide sic cyclone parts / cyclone lining with high hardness with high strength,high wear resistance, corrosion resistance, high temperature resistance, which has been widely used as the liners or parts in corase particles classification, concentration, paper making, chemical, electronics, washing and mineral processing industry.

Property Of Silicon carbide Lined Cyclone

*Superior wear resistance, impact resistance and corrosion resistance

*Excellent flatness and temperature resistance up to 1380℃

*Excellent oxidation resistance

* Good dimensional control of complex shapes

*Easy installation

* Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane)

Applicaion of RBSiC ( SiSiC ) silicon carbide sic cyclone parts / cyclone lining with high hardness

RBSiC ( SiSiC ) silicon carbide sic cyclone parts / cyclone lining with high hardness has high hardness, high temperature, abrasion resistance, oxidation resistance, acid and alkali resistance characteristics,which is widely used for wear-resisting lining of hydraulic cyclones, flue gas desulphurization pipes and coal slurry conveyor pipelines.

Thickness available: 4mm - 25mm

Shape available: Tubes , Tee pipes, Elbows, Cones, Rings and so on.

Other RBSiC / SiSiC reaction bonded silicon carbide products

The main products of reaction bonded silicon carbide ceramics are: cross beams, rollers, coling air pipe,burner nozzles,thermocouple protecting tubes,temperature measuring parts, radiant tubes, desulfurization nozzles, crucible,batts, wear resistant lining materials,plates, seals, rings and special shaped structural parts.

Cyclone Components Commonly Subject to Wear

There are many components within a cyclone assembly that are subject to high wear conditions. Taylor Ceramic Engineering can supply many of these in wear resistant materials to extend component life. Some of the parts that we typically supply include:

• Cylindrical & Reducing Liners

• Inlets

• Outlets

• Spigots

• Inserts

• Upper, Mid & Lower Cone Sections

• Vortex finders

• Virtually any surface that undergoes wear

Wear Resistant Lining Formats

The Diameter and Lining Materials of Cyclone

| No. | Diameter Φ mm |

Lining Material |

| 1 | 350 |

Alumina |

| 2 | 380 |

Silicon Carbide |

| 3 | 466 |

Polyurethane |

| 4 | 660 |

/ |

| 5 | 900 |

/ |

| 6 | 1000 |

/ |

| 7 | 1150 |

/ |

| 8 | 1300 |

/ |

| 9 | 1450 |

/ |

Some of the parts that Yiho typically supply include

• Cylindrical & Reducing Liners

• Inlets(Allows for a range of volumetric flow rates to be accommodated by a single cyclone diameter)

• Outlets

• Spigots

• Inserts

• Upper, Mid & Lower Cone Sections

• Vortex finders(Allows for a wide range of sinks yields to be accommodated)

• Monolithic Cyclone