CERAMIC CLINDER FOR EXTREME WEAR PROTECTION

Applications

CERAMIC LINER FOR EXTREME WEAR PROTECTION

Mineral Processing equipment operates in some of the harshest and remote locations. It is crucial to the Mineral Processing industries that this equipment continues to operate efficiently and its life cycle is maximized to minimize down time. By appropriately protecting equipment from the extreme wear caused by the high speed and flow rates of ore when processed as a slurry ensures better equipment longevity. Slurry is highly abrasive and can not only cause wear damage to wet processing equipment but also with the inclusion of chemicals and heat, there is constant risk of corrosion and dangerous leakage.

Wear Protection Linings are used throughout Mineral Processing to protect the steel surfaces of equipment from wear and corrosion. They are used on a range of equipment including pipes, tanks, chutes, pumps, flotation cells, thickeners, launders and feed spouts or chutes.

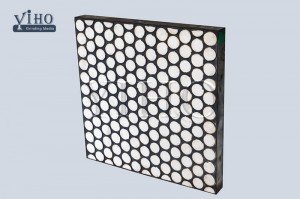

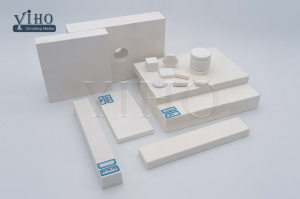

Composite Ceramic Wear Liners are ideally suited for wear and corrosion protection with the inclusion of extremely high wear resistance ceramic tiles coupled with the impact and energy absorbing resistance of the rubber matrix. This combined effect significantly reduces wear, leakage and the risk of damage to the equipment but also significantly decreases environmental and safety issues for operators.

Ultraming supply a range of custom made Composite Ceramic Wear Liners made only from Alumina tiles embedded within a premium grade, wear and impact resistant rubber. These products are designed to be bonded into equipment using the CN bonding layer for ultimate bond strength and can be easily installed in place of existing lining materials such as steel or rubber.

Composite Ceramic Wear Liners can be supplied as standard pads, or cut panels to meet customer drawings and specifications, or can be custom engineered to ensure maximum suitability for your specific application.

Ceramic Wear Panels can also be supplied with steel backing for mechanical fastening onto equipment for quicker and easier replacement.

Ultraming Composite Ceramic Wear Liners last longer, requiring less change-outs, reducing downtime and increasing the productivity of your equipment.