RUBBER-CERAMIC WEAR LINERS

Wear Liners from Yiho

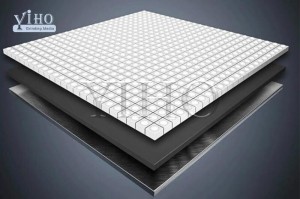

Rubber-Ceramic Wear Liners are suitable for applications in areas of severe impact and areas of high abrasion. Liners can be supplied to incorporate a variety of ceramic shapes, including balls, cylinders and cubes, all of which have a high alumina silica content that withstands severe impact and high abrasion.

Ceramic material can be as follows

- 92%/95%/99% Alumina

- ZTA(zirconium Toughened Alumina)

- Zirconia

- Silicon Carbide (Reaction Bonded)

Wear liners are suitable for use in process plants, power generation and materials handling industries, among many others.

RubCer Composite Wear Products: Embedded ceramic in rubber bases provides enhanced wear and impact resistance for plants.

Magnetic Liners:Magnetic Liners provide an effective, highly resistant lining solution.

Cast Basalt Wear Resistant Material:Fit your plant with maximum hardness lining for enhanced wear resistance.

Ceramic Wear Resistant Tiles:Our customised engineered ceramic solutions provide wear resistance up to 350° C.

Bonding & Mounting

We uses the best available technology to bond the ceramic and rubber together. A special coating is applied to the ceramics prior to molding at high temperatures and extreme pressure for an extended time creating a molecular bond between the coating and the rubber. The ceramic cannot be pulled out of the rubber.

Rubber-Ceramic Benefits

- Modular Bolt-In Sections

- Not Limited to Standard Sizes and Thicknesses

- Highly Customizable

- Fast Installation & Replacement

- Cost Effective

- Impact Absorbing

- Abrasion Resistant

- Noise Reduction

- Lighter Compared to Steel