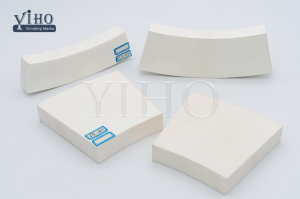

Ceramic wear plates for aggressive abrasion

Wear plates for demanding environments

Ceramic wear plate has a very high resistance to mechanical abrasion and erosion. They are used with advantage as construction materials in truck dump bodies and barges that load and unload excavated gravel and rocks, for heavy steel scrap handling and at demolition work where concrete with iron reinforcement bars is released on the flat bed.

Lower noise level

The ceramics of the plates are mounted in a steel frame or vulcanized in rubber, which increases the resistance to impact and reduces the noise level due to rubber’s shock absorbing properties. They can be bolted or glued directly to the surface of the wear plate.

Manufacturing according to specification

Yiho always delivers an optimized solution where our ceramic plates are manufactured according to customer specifications. Taking into account, among other things, application and material flow, type of ceramic, dimensions and thickness, with or without rubber insertion, etc.

Ceramic Material:Silicon Carbide

Silicon Carbide (SiC)

Silicon carbide is formed in two ways, reaction bonding and sintering. Each forming method greatly affects the end microstructure.

Reaction bonded SiC is made by infiltrating compacts made of mixtures of SiC and carbon with liquid silicon. The silicon reacts with the carbon forming more SiC which bonds the initial SiC particles.

Sintered SiC is produced from pure SiC powder with non-oxide sintering aids. Conventional ceramic forming processes are used and the material is sintered in an inert atmosphere at temperatures up to 2000ºC or higher.

Both forms of silicon carbide (SiC) are highly wear resistant with good mechanical properties, including high temperature strength and thermal shock resistance. Our engineers are always available to best advise you on the strengths and weaknesses of each ceramic for your particular needs.

Typical silicon carbide characteristics include:

• Low density

• High strength

• Good high temperature strength (reaction bonded)

• Oxidation resistance (reaction bonded)

• Excellent thermal shock resistance

• High hardness and wear resistance

• Excellent chemical resistance

• Low thermal expansion and high thermal conductivity

Typical silicon carbide applications include:

• Fixed and moving turbine components

• Seals, bearings, pump vanes

• Ball valve parts

• Wear plates

• Kiln furniture

• Heat exchangers

• Semiconductor wafer processing equipment

For further information on our silicon carbide and how this can be used for your product, contact us today