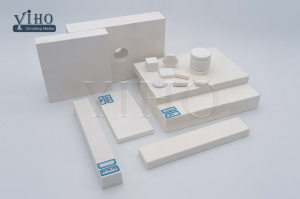

Dry Pressed Alumina Wear plate

About YIHO Alumina Wear Plate

Increase the life and performance of your operational assets.

Wear Plates are designed and manufactured for their specific intended application, ensuring the correct plate is always recommended and installed.

In addition to the sale of wear plates, HICTECH offers installation capabilities which deliver exceptional customer satisfaction and value. Facilitated by our experienced and reliable onsite service division, we will take control of your whole project, from the conception and evaluation stage, through to the manufacture, delivery, installation, maintenance and ongoing after sales service/support.

Wear plates are engineered to suit each application and have various fixing options, steel studded backing plates, weld on options and direct substrate bonding.

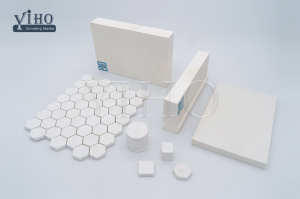

Alumina Ceramic Wear Plates

Wear Plates are manufactured to the highest quality standards and specifications, making them far superior to any other product in the market.

Features

• Superior wear characteristics

• Dampens impact

• Noise reduction

• Reduces downtime

• Low cost per tonne ROI

• Fit for purpose

Alumina Wear Plate Applications

• Chutes

• Hoppers

• Transfer points

• Crushing and screening

• Milling

• Train and ship loaders

Alumina Wear Plate Specification

|

Composition |

Thicknesses |

Density |

|

Zirconia Toughened Alumina |

12mm,25mm,50mm |

4.2gr/cm3 |

|

Alumina 92% / 95% Al203 |

3~75mm |

3.65&3.72gr/cm3 |

|

Alumina 92% Al203 / Natural Rubber |

8mm-63mm |

/ |

|

Alumina 92% Al203 / High Tensile Polymer |

10mm-63mm |

/ |

|

Polyurethane |

3mm-20mm |

/ |

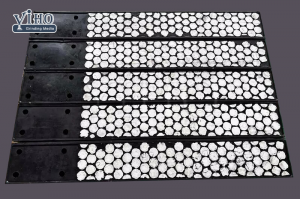

Installation of wear ceramic liner

1. Directly adhesive paste: use room temperature or high temperature strong inorganic adhesive paste to install. It is easy to install and suitable for small impact with the working temperature below 350℃.

2. Stud welding: it can be used for high temperature materials and materials with high impact force. The mechanical self-locking force and inorganic adhesive can ensure that the liner does not fall off.

3. Prefabricated ceramic liner installation: ceramic need to be installed on the steel plate firstly to make a 2-in-1 ceramic liner (ceramic + steel plate), or 3-in-1 ceramic liner (ceramic + rubber + steel plate), and then through welding or countersunk bolts to install it on the equipment, which are easy to repair and replace.

High Purity Alumina impact-resistant wear-resistant ceramic Lining Plate

can replace the manganese steel liner, which can fundamentally solve the wear problem. The high temperature impact-resistant wear liner is welded in the equipment by stud welding of toughened ultra-thick ZTA, so as to form a strong anti-wear layer. Some spherical bulges can be designed on the lining to further enhance its impact resistance. For ease of installation and replacement, the ceramic liner can be mounted on the steel plate and then mounted on the equipment by welding or countersunk bolts.