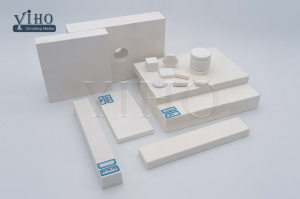

Mosaic mats alumina ceramic linings pieces

Ceramic mosaic is widely used as a lining (facing) tile in the conveyor equipment to protect the drive pulleys of belt conveyors from wear, increases the tape engagement ratio, excluding its slippage.

The mosaic mats consist of small mosaic tiles glued to acetate silk or PVC mounting film. Standard mats are 150x150, 300x500 and 500x500 mm. Standard thickness is 3-12 mm. The mats consist of a square tile of 10x10 or 20x20 mm, or a hexagonal tile of SW20 mm. Special sizes are on the Customer's request.

Material of Ceramic Lining Pieces

Alumina content: 92%, 95% and 99%

Type of Alumina Ceramic Linings

Alumina ceramic linings consist of individual pieces or tiles made from alumina ceramic material. These ceramic linings are used to protect various equipment and surfaces from wear, abrasion, and impact in industrial applications. Here are some common types of alumina ceramic lining pieces:

1. Alumina Ceramic Tiles: These are square or rectangular-shaped tiles made from high-purity alumina ceramics. They come in various sizes and thicknesses to fit different applications and equipment.

2. Alumina Ceramic Bricks: Alumina ceramic bricks are larger and thicker pieces of ceramic linings, often used in heavy-duty applications that require maximum wear protection.

3. Ceramic Cylinders: Alumina ceramic cylinders are used to line cylindrical equipment, such as pipelines, chutes, and cyclones, providing protection against abrasion and impact.

4. Ceramic Plates: Alumina ceramic plates are flat pieces of ceramic linings used to protect larger surfaces or equipment components.

5. Ceramic Hex Mats: Hexagonal-shaped alumina ceramic mats are designed to interlock with each other, creating a continuous lining on large surfaces, providing effective wear protection and minimizing material build-up.

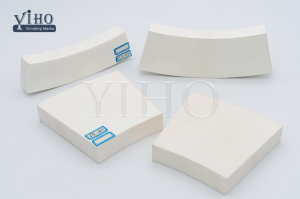

6. Ceramic Lagging Tiles: These tiles are specifically designed for lagging applications, providing wear resistance on conveyor pulleys and similar components.

7. Ceramic Lined Elbows: Alumina ceramic pieces are custom-shaped to fit the curves of elbows and bends in pipelines, ensuring wear resistance in high-velocity abrasive material flows.

8. Ceramic Lined Pipes: Alumina ceramic linings can be engineered to line the interior of pipes, protecting them from erosion and abrasion caused by the flowing materials.

9. Ceramic Chute Liners: These are custom-shaped ceramic pieces used to line chutes and hoppers, protecting them from the impact and wear of bulk materials.

10. Ceramic Wear Pads: Alumina ceramic wear pads are smaller, customized pieces used in specific areas prone to high wear.

Application as ceramic pulley Lagging Tiles

Packing of Ceramic Tiles of Ceramic Lining Pieces

25kg pp bag on pallet