Abrasion & lmpact resistant Ceramic Wear Linings

-

Monolithic Silicon Carbide Cyclone and Hydrocyclone Liners

YIHO also produces monolithic drop-in replaceable silicon carbide cyclone and hydrocyclone liners specifically engineered for separating and classifying applications. These ceramic liners are designed for highly abrasive ores including coal, iron, gold, copper, cement, phosphate mining, pulp & paper and wet FGD and are available in sizes up to 60″ in diameter.

-

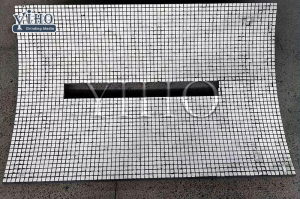

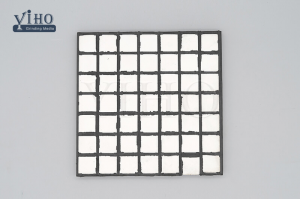

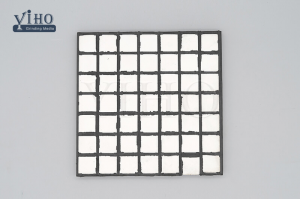

Mosaic mats alumina ceramic linings pieces

Ceramic mosaic is widely used as a lining (facing) tile in the conveyor equipment to protect the drive pulleys of belt conveyors from wear, increases the tape engagement ratio, excluding its slippage.

-

Hybrid Liner Rubber Ceramic Matrix

Joined using a special process, the Hybrid Liner combines two liner materials and their favorable properties. The interior is made of polyurethane and protects the residual limb and bony structures thanks to its shock absorbing characteristics. At the same time, it ensures optimum pressure distribution across the entire residual limb, both for passive and active generation of the vacuum. The outside of the liner and the integrated vacuum flap are made of silicone, proven in everyday use thanks to its robustness. This is particularly important when the vacuum flap is folded over the inner socket to create an airtight seal for the system.

-

Hot Vulcanization Rubber Ceramic Composite Wear Panels

YIHO Wear Panel solutions are ideal for a wide variety of mining, mineral processing and material handling for protection against extreme wear.

-

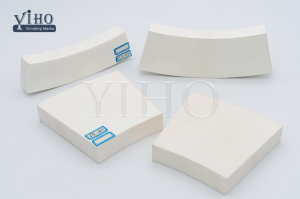

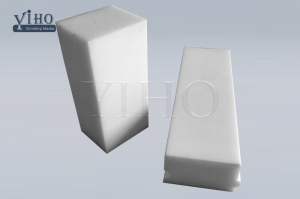

High-Performance Y-ZrO2 Zirconia Tile for Industrial and free contamination Environments

Zirconia (Zro2) ceramic offers a combination of high hardness, wear and corrosion resistance, while exhibiting one of the highest fracture toughness values among all ceramic materials.

-

High purity oxide alumina ceramic tiles

Yiho premium alumina ceramics are manufactured by blending and mixing specified ratios of high-quality raw materials such as alumina powders, oxides, lubricants, dispersion agents, binders and water using a ball mill method. The slurry then goes through a spray drier before the pressing stage. Low percentages of organic binders allow the alumina particles to bond together and form a green un-sintered body during the pressing stage. Once pressed to size, pre-heating takes place followed by sintering through a tunnel kiln. Sintering temperatures and times are strictly followed to ensure binder burn out is optimized and that explosive spalling does not take place.

-

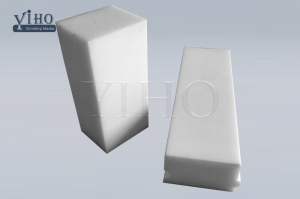

High alumina Weld-on wearing tiles

Ceramic tiles have excellent abrasion and wear resistant qualities and are ideal for use in transfer chutes, piping systems, hoppers, etc. Typical markets include grain, coal-fired power generation, mining, cement, and more.

-

High alumina Ceramic Wear resistant Tiles

Alumina ceramic tiles for coal and other material handling and processing industries. Ceramic linings provide long-lasting solutions to the problems caused by abrasive wear and corrosion in a variety of hostile environments. Alumina ceramic linings will outlast lower grade materials commonly used to line or protect processing and material handling equipment, including Basalt, stainless steel, carbon steel and wear resistant plates, by factors of 3 to 15 times.

-

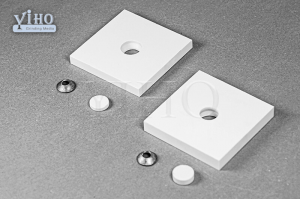

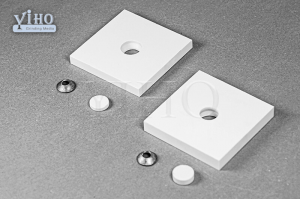

Impact & Abrasion Resistance Rubber Backed Ceramic Liner

Alumina ceramic lining plate is a high abrasion-resistant wear product, it is a combination of high alumina ceramic tiles and natural rubber.

High alumina ceramic lining offers wear protection and can extend service life of chute or other equipment significantly, wear life of high alumina ceramic is approx. 5 timers longer than rubber and 10 times longer than steel.

-

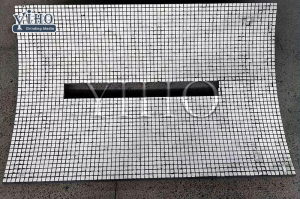

Hexagonal Tile Type Wear Resistant Rubber Ceramic Mat

Wear Resistant Rubber Ceramic Panels is new generation composite panels, a combination of wear resistant alumina ceramic cylinders/ceramic tiles vulcanized in resilient rubber base. The alumina ceramic surface provides exceptional resistance to wear, while the elastic property of the rubber effectively dampens the impact forces which can crack the ceramics. Rubber also helps to substantially reduce the vibrations, sounds, and the impact shock generated from impacting rocks. Laid out in zigzag and brick pattern, ceramic tiles/cylinders is an excellent feature for handling large material volumes at different angles without developing a wear pattern. As excellent impact and wear resistant material,The panel is suitable for feeders, chutes, bins, transfer points, in conveyor systems, screen feed plates, mill discharge chutes, bunker etc. The major applicable industries are Coal fired power plants, cement plants, blast furnace plants and host of other industries which requires high impact abrasion resistant surfaces.

-

HEAVY WEAR PROTECTION Ceramic Rubber Liner Materials

Yiho offers a number of custom wear-resistant rubber-ceramic liner solutions that provide long-term protection for Mining equipment.

-

HEAVY DUTY SKIRT LINERS (CERAMIC CANOE/Skirt LINERS)

YIHO has been manufacturing wear liners of all types for over 25years. From Bolt on to weld in, canoe liners or skirting liners, with steel back or ceramic face we can supply all your requirements.