Abrasion & lmpact resistant Ceramic Wear Linings

-

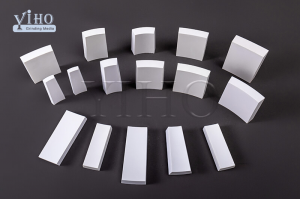

Abrasive Materials Wear-Resistant Alumina Ceramic Ball Mill Lining Brick

Alumina ceramic ball mill lining bricks are used to line the inner shell of ball mills, thereby protecting the steel shell from the abrasive and often harsh conditions of the milling process. These bricks are made from high-quality alumina ceramic materials, which have excellent mechanical properties such as high hardness, wear resistance, and impact resistance.

-

92% Alumina Ceramic Sleeve for wear resistance

By cold isostatic pressing process, alumina ceramic sleeves have the advantages of high hardness and abrasion resistance,defined and uniformly low erosion,dimensional stability and low specific weight.

-

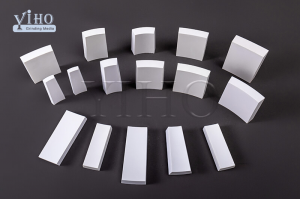

92% /95%/99% Al2O3 Ceramic plain Tile

Ceramic Alumina Tiles are specially designed using industry expertise to combat the effects of wear on your mineral processing and bulk handling equipment. Our high-content Ceramic Alumina Tiles, with a fine crystalline structure.

-

Polyurethane milling & Grinding Jar

High wear-resistant polyurethane mill jar has an excellent performance in electronic industry and battery material.It does not bring harmful impurities into grinding materials in working process,and ensures quality of the electronic products.

-

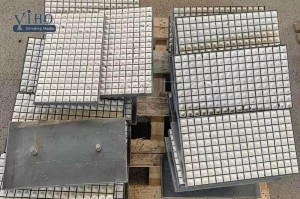

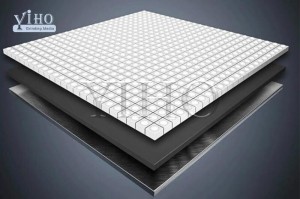

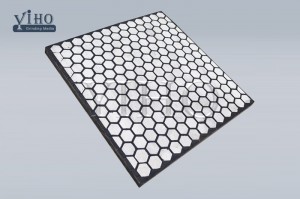

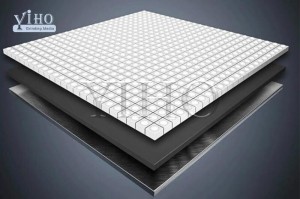

2 in1 or 3 in 1 Composite Ceramic Wear Plate

Composite ceramic rubber wear plate.

Excellent wear resistance, wear life of high alumina ceramic is approx. 5 timers longer than rubber and 10 times longer than steel.

More impact resistant, rubber or polyurethane cushions makes more impact resistant.

Available in irregular shapes and sizes.

-

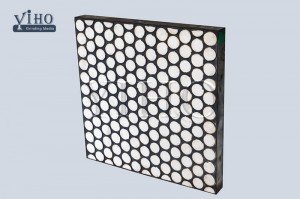

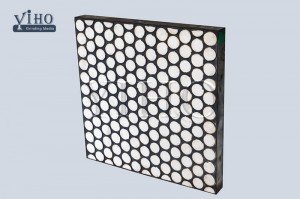

Ceramic wear plates for aggressive abrasion

Ceramic wear plate is used in truly aggressive environments where heavy flows of rough materials causes impact and strain on the equipment. Ceramic wear plate contributes to better abrasion resistance, higher payload and much longer service life.

-

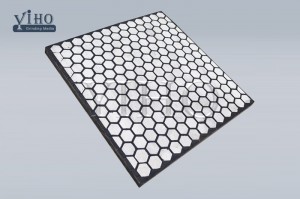

RUBBER-CERAMIC WEAR LINERS

The majority of our wear liners are designed for use in the process plant, power generation and material handlings industries. Wear lining materials used include ceramic linings, ceramic composites, rubber wear plates that include ball mill liners and profile liners among many others, basalt linings, epoxy wear compounds

wear liner solutions protect your materials handling chutes, bins and tanks and improve the flow of material through your plant. Our installation teams undertake complete installation of your wear liners and provide assistance and/or supervision when required.

-

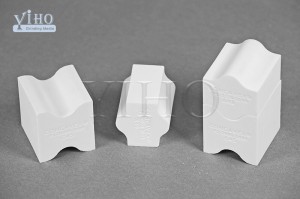

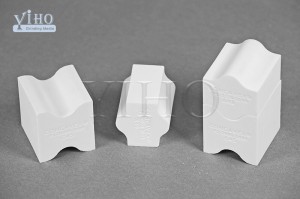

Impact Ceramic Block/Cube

The Ceramic Cube is a high-performance abrasion and impact resisting linings for high-impact, high-pressure applications in which ceramic tile may not have sufficient structural resistance, and high-performance rubber may not offer the required wear life. In extreme applications, the Cube liners can be installed in a matrix or abrasion resistant steel plate to provide structural support for the ceramic/rubber matrix and provide exceptional wear life where competing products cannot.

-

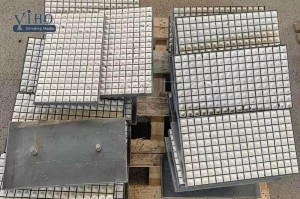

Wear resistant steel-rubber-ceramic panel vulcanized ceramic plates

In aggressive industrial applications, equipment where high impact , high abrasion inevitably suffer mechanical attack, chemical attack, corrosion, or by a combination of these three modes.

YIHO’s Ceramics can offer various of ceramic liner plate for customer’s abrading environment. Composite ceramic wear liner is intended for the toughest applications with very high materials. when a combination of extreme wear and impact resistance ans long wear life is needed , Ultraming offer composite ceramic wear liner with large and hard ceramic bricks vulcanized into a matrix of wear resistant rubber .due to its elastic properties the rubber acts as a dampener. It makes it possible to use this product in applications with a lot of impact without the risk of crushing the ceramic bricks .

-

CERAMIC CLINDER FOR EXTREME WEAR PROTECTION

Mineral Processing equipment operates in some of the harshest and remote locations. It is crucial to the Mineral Processing industries that this equipment continues to operate efficiently and its life cycle is maximized to minimize down time. By appropriately protecting equipment from the extreme wear caused by the high speed and flow rates of ore when processed as a slurry ensures better equipment longevity. Slurry is highly abrasive and can not only cause wear damage to wet processing equipment but also with the inclusion of chemicals and heat, there is constant risk of corrosion and dangerous leakage.

-

Industrial ceramic wear tiles

Wear-resistant elements prevent destruction in the transportation, processing, mining and other technological equipment. The elements are made of high-purity, finely dispersed, alpha-alumina. Wear-resistant plates can be made from a variety pre-designed element of different dimensions and forms.

-

Ceramic tubes and special-shaped parts

Wear resistant ceramic which are mainly composed of at least 90% Al2O3 are the most widely used in the world today.

Our products are made from strictly selected alumina powder with uniform particle sizes and low CaO content.Wear resistant ceramics can be made through common dry press or isostatic pressing process and then sintering them at high temperature in the kiln. They are desirable lining materials for high wear equipment due to precise dimensions, high density,high alumina content,good flatness and stable quality.